Revolutionary restoration of classic cars: the role of 3D scanning in reviving the vintage BMW E9.

Intersection of 3D Scanning and Restoration of Vintage Cars

Before the advent of 3D scanning technology, many classic cars led a difficult existence. A significant number of them were subjected to improper repairs or even complete destruction. Identifying bent or broken parts that caused problems for the car could be a difficult task, even if some damage was visible. To accurately diagnose the problem and find a solution, Raimo, an expert in car restoration, turned to the portable 3D scanner - EinScan Pro 2X Plus. This article explores how this innovative technology has changed the restoration process.

Trials in Restoring BMW E9

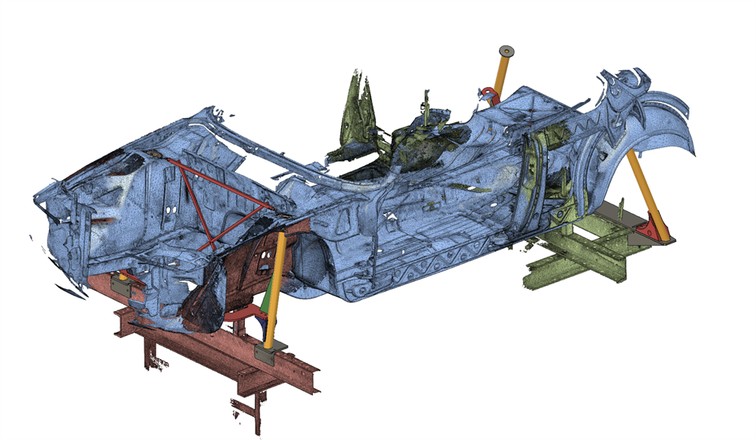

Rebelliontech OÜ, an Estonian car restoration company, specializes in servicing and repairing vehicles. They faced a serious problem with a BMW E9 that had been stored in a barn in Germany for several years. The car had been completely disassembled, with most of its parts missing, including a significant portion of the body. The previous owner had started the restoration, but for unknown reasons abandoned the project. Fortunately, Raimo had recently restored another BMW E9, which allowed him to obtain valuable information and a strategy for implementing this project using a handheld 3D scanner.

Possibilities of 3D Scanning in Car Restoration

Compared to traditional manual measurements, 3D scanning provides a faster, more accurate, and detailed data collection process for car repairs. Raimo wanted to compare the scan data of the BMW E9 with a previously restored model. Upon the car's arrival in Estonia, he performed a 3D scan of the body using EinScan Pro 2X Plus. This comparison allowed Raimo to identify the missing chassis parts that needed restoration.

Using Deviation Data for Comprehensive Restoration

Simply identifying missing parts was not enough. Raimo imported the data into 3D inspection software, which allowed him to obtain the deviation between the remaining part of this BMW E9 and the previous one. This step was crucial, as the deviation data allowed the repairmen to better assess the extent of chassis damage, leading to a more comprehensive restoration strategy.

Final Design and Restoration with CAD

"3D scanning played an important role in finding the correct points on the body. With the 3D model, a metal frame could be created to determine the main points of the car," Raimo explained. Thanks to accurate car modeling and fast export to CAD, 3D scanning technology significantly reduced the time required for measurements and accelerated the customization process."

The first stage of restoration is complete, with the panels correctly positioned. When the restoration moves on to the engine installation stage, the role of the 3D scanner remains crucial.

*Note: The 3D scanner referenced in this article has been upgraded - EinScan Pro 2X 2020 and EinScan Pro HD.