Promising directions for the development of 3D printing

3D printing is an extremely promising technology that has the potential to change the principles of manufacturing many things. In addition, the use of 3D printers will significantly reduce the production time of various products and lower their final cost. Let's consider in which areas the use of 3D printing is most promising, what future this technology holds, and how quickly it will develop.

- Relevance of 3D printing

- Perspectives of 3D printers in different spheres

- Future of 3D printing

- Unexpected opportunities of 3D printing

- Who determines the future of 3D printing?

- What awaits 3D printing in the next few years?

- Revolution in materials

- What are the unusual projects of the technology of the future?

Relevance of 3D printing

3D printing technology is relevant due to its simplicity of use and the time savings in the production of various types of products.

Printing three-dimensional objects also provides highly accurate reproduction of necessary forms and details of a particular object. At the same time, manual labor is practically reduced to zero, which means that the costs for the operator and maintenance of the 3D printer will be minimal. This will ultimately reduce the manufacturing cost of the finished product.

Thanks to such advantages, 3D printing is successfully used in many industries and in everyday life.

Perspectives of 3D printers in different spheres

3D printing technology has quite large perspectives when used correctly. The following areas of activity are most in need of 3D printing services:

- Construction. 3D printing can become a significant support in the construction industry compared to traditional construction methods. Successful experiments in the creation of building elements and houses have already been carried out in China and the UAE.

- Electronics. In the production of digital devices, 3D printing will reduce the time required to manufacture intricate details, microchips, and hardware. Graphene-based batteries with unlimited durability are already being developed using 3D printing.

- Machinery and automotive industry. In this sphere, experimental models of future parts and details are 3D printed to allow for the production of high-quality products in the future.

- Aerospace industry. 3D printing is used to create innovative constructions of any complexity using metal, polymers, and other super-strong materials for satellites, rockets, and other space objects.

- Medicine and pharmaceuticals. 3D printing is crucial in creating prototypes of human organs, prosthetics, implants, and even the development of real organs that will integrate well with the human body. In the pharmaceutical industry, 3D printing is mainly used for creating tablets that gradually release active substances after ingestion.

- Advertising. 3D printers are used to print prototypes of various products, demonstration, and promotional materials.

- Food industry. 3D food printers are especially interesting because they allow for the creation of edible objects from common products and the unique decoration of food items with high precision.

Future of 3D printing

With proper development and study, 3D printing will be more accessible in the future, as 3D printers will be widely used in many industries. Equipment prices are likely to drop as they will be produced by various companies in large quantities to meet the demand of all buyers.

The high demand for 3D printing will lead to the development of new types of 3D printers and materials for creating products. Large-scale equipment for more volumetric 3D printing will also be developed, allowing for the printing of very large items for construction, engineering, and other industrial applications.

Unexpected opportunities of 3D printing

In addition to standard 3D object creation, 3D printers also allow for the development and printing of unique and personalized products. The form, structure, and construction characteristics of these products are limited only by the user's imagination. Unusual items such as non-melting ice sculptures, perfectly cooked pancakes, or finely crafted jewelry can be produced.

Who determines the future of 3D printing?

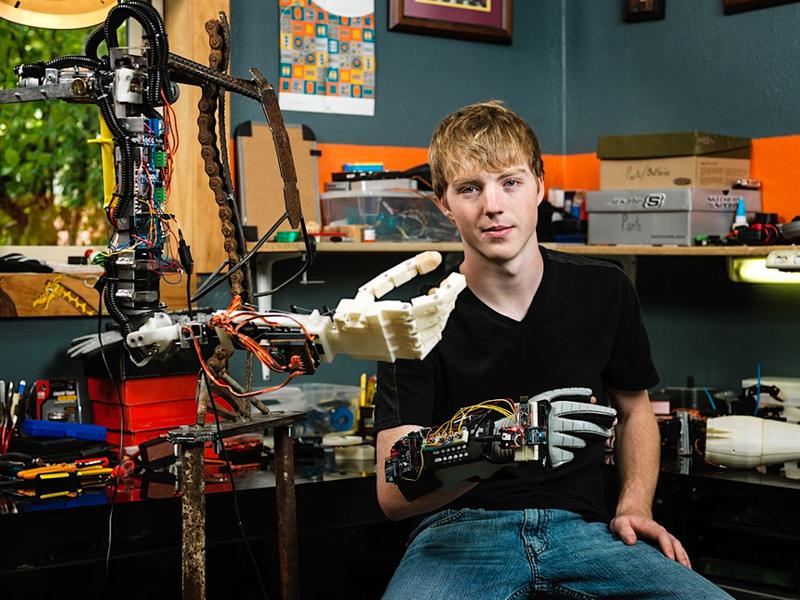

The future development of 3D printing depends primarily on inventors who create new types of printers and develop new printing technologies depending on the type of material used. Innovations in 3D printing most often come from research centers, industrial enterprises, and technical departments of various universities. In addition to scientific researchers and students, a large number of developments are done by children and enthusiasts of 3D printing, such as the invention of the first prosthesis printed on a 3D printer by 17-year-old Easton LaChappelle.

In addition to inventors, the stable development and improvement of printing methods are also the responsibility of organizations that sponsor new developments.

Information. The three best-known companies in the field of 3D printing are Shapeways, Sculpteo, and Materialise. They are involved in professional development and production of new 3D printer models, materials, as well as the improvement of existing technologies and the creation of new ones.

What awaits 3D printing in the next few years?

Experts predict the following developments in 3D printing in 2021:

- Widespread use of 3D printing for creating three-dimensional objects, just as photocopying and printing studios are common. 3D printing will be carried out both for standard models and individual projects.

- The mass production of various products using 3D printing, resulting in significantly lower prices for finished products.

- Medical scientists will master the creation of fully compatible organs printed from human cells on 3D printers.

- After confirming the safety of 3D printing for construction purposes, many companies in this industry will start using powerful industrial printers to create necessary building elements, reducing construction time and decreasing the need for manual labor.

Revolution in materials

3D printing typically uses plastic materials as filaments. However, the technology is developing rapidly, leading to the emergence of innovative materials such as:

- Metal powder. During printing, this material is mixed with polymer and used in the technology of laser sintering of metals, resulting in products printed from the mixture having increased strength comparable to real metal.

- Graphene. This carbon material is used experimentally to develop a new composite. Ideally, a graphene sheet printed by a 3D printer will be as thin as a molecule and ten times stronger than steel.

- Ceramic foam. This material has flexible characteristics that can be changed depending on the intended use. It is possible to print very lightweight figures or heavy monuments from ceramic foam using a 3D printer. Although the development exists in theory, it requires testing and stabilization of functional properties.

What are the unusual projects of the technology of the future?

Among the unusual 3D technologies of the future, special attention should be paid to:

- Creating personalized clothing and footwear based on 3D body scanning;

- Makeup created by portable 3D printers, which is both fast and precise in creating fine details;

- Bioprinting using living cells to create tissues and organs from hydrogels.

3D printing holds great promise in various industries and human life activities. The technology will replace heavy labor, print cheaper products with consistently high quality. However, not all industries can immediately use 3D printing, as it will require years of testing and a series of assessments.