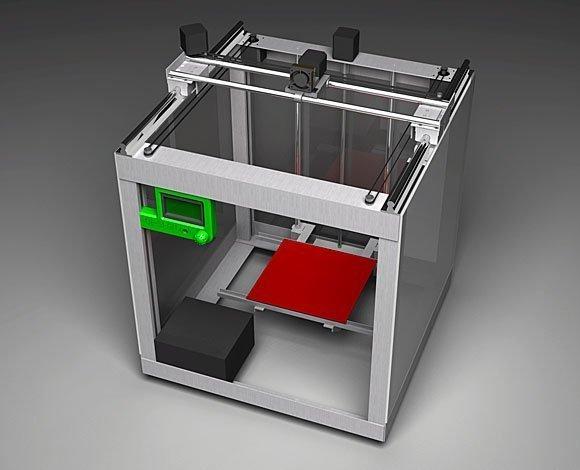

How to make a 3D printer from aluminum profile by yourself?

Not all novice printers can afford a new 3D printer. It is a rather expensive pleasure. Also, it is necessary to be sure that the model is suitable for performing the necessary tasks. It turns out that the only budget way to touch the world of 3D printing is to build a printer yourself.

- Why build a 3D printer out of profile and what are the ways?

- Advantages of creating a 3D printer with your own hands from aluminum profile

- How to make?

Why build a 3D printer out of profile and what are the ways?

Usually, 3D printers are assembled by hand for the following reasons:

- Lowering the cost of construction.

- Creating a more perfect device than those offered in the market.

- Making a device according to specific requests and needs, if the printer is intended for specific specialized tasks.

- Desire for self-expression. There are people who make high-tech equipment just for fun. After that, they offer materials on creating a printer for consideration by a large audience of enthusiasts.

Self-assembly of a 3D printer requires a deep immersion by the master into the principles of the operation of such devices, as well as experience working with components.

There are two options for building a device on your own:

- Using kits. Devices are provided to users in a disassembled form. Such sets usually contain all the necessary fasteners and details if they are sold by 3D printer manufacturers. In kits from independent projects, there may be only a set of components, or only parts for the case. Their cost is much lower and at the same time allows the buyer to embody their creative ideas.

- Independent project. This method is much more difficult. It is necessary to make many calculations and analyze the characteristics of all the components.

For economy, some craftsmen use frames of their own production. The most suitable material for this is aluminum.

Advantages of creating a 3D printer with your own hands from aluminum profile

Advantages in using aluminum profile for making a device:

- Greater strength with relatively small weight.

- High viscosity of aluminum, which allows damping vibrations.

- Convenient assembly. For this, only bolts and T-nut are used.

- Simple preparation. The profile just needs to be cut into pieces of the required length.

- It is drilled and cut easily, the finished product can be easily disassembled and modernized.

- Thanks to the profile's geometry, a structure of high rigidity can be assembled from it.