How to avoid shrinkage of PLA plastic during printing?

Plastic PLA - one of the most popular materials used in 3D printing today. This filament is convenient to use, does not have a strong odor, is non-toxic, and is made from renewable resources. Thanks to its technical characteristics, it can be used to print voluminous 3D models of various types, but only if the technological nuances are observed. Otherwise, the product may deform, and the plastic may shrink.

- Causes of deformation of PLA models

- Why does PLA plastic shrink?

- How to avoid shrinkage?

- Printing errors and how to avoid them

Causes of deformation of PLA models

PLA plastic is a polylactic acid, a thermoplastic polyester derived from corn starch, tapioca roots, or sugar cane. This material is widely used in manufacturing, including the food industry. PLA plastic has a relatively low melting temperature - only 80°C, so other plastics are added to the material during filament production, making it suitable for use in 3D printers.

PLA plastic has minimal shrinkage, threads made from this polymer are stiffer, less susceptible to wear, and models printed with this filament have a smoother and more attractive surface.

The increased hardness and stiffness make the material quite brittle. Therefore, PLA is not suitable for printing parts that will be subjected to serious mechanical stress during use.

In addition, PLA is not suitable for use in high-temperature conditions - due to its low melting temperature, the product will lose its rigidity after 70°C, shrink, and deform.

Shrinkage can also occur during the printing process due to differences in the temperature regime inside the product and on its surface. A sharp temperature difference will cause the edges of the model to lift and the entire product to deform.

Shrinkage can also occur due to excessive free space in the printing box. The problem arises when the power of the table is insufficient to sufficiently heat the thermal box space throughout the volume of the printing model.

Shrinkage can occur due to poor adhesion of the part to the surface of the work table. If the adhesion is insufficient, internal stress (shrinkage) will overcome its forces, and the product will lose its shape.

Shrinkage of PLA plastic can also occur due to the low layer bonding temperature coefficient. If the force of internal stress exceeds the bonding force of the layers, there will be a rupture, and cracks will appear on the surface of the model.

The 3D printing process can also be disrupted by the lack of honesty of the filament manufacturer. Due to the effect of liquefaction, that is, the heterogeneity of the chemical composition formed during crystallization, the model will not lose its external attractiveness, but its final operational characteristics will noticeably decrease. More often, chemical heterogeneity occurs when the manufacturer does not control the purity of the plastic formula.

Why does PLA plastic shrink?

Shrinkage is the property of a polymer material to decrease in volume during the solidification process. The effect is expressed in percent and directly depends on how pure the filament's chemical composition is, as well as the melting temperature of the polymer and the temperature in the thermal box during 3D printing.

IMPORTANT! Typically, high-quality materials have a shrinkage ratio of no more than 0.5%, while low-quality materials can have a shrinkage ratio of up to 4-5%.

It is worth noting that the first layers of the product are more susceptible to shrinking, since this area is constantly heated due to the energy transmitted by the printer table, and the difference between the temperatures of the subsequent layers.

How to avoid shrinkage?

In order to avoid shrinkage and deformation of models made of PLA plastic, it is recommended to follow the rules listed below.

- Improve adhesion. How strong the first layers of the model are adhered to the work surface directly affects the final quality of the product. Adhesion can be improved by changing the material of the work table - there are surfaces made of aluminum, glass, basalt, titanium, etc. A popular means of increasing adhesion is a special polyamide film, which is applied to the work table before printing. In some cases, this film is additionally treated with sandpaper - a cleaned surface will increase adhesion to the plastic. Adhesion can also be improved by applying a special aerosol glue or hair lacquer.

- Reducing deformation can also be achieved by reducing the printing speed. This will increase the time spent, but will lead to uniform cooling of the layers, reducing the likelihood of excessive material shrinkage. This rule is extremely important for printing with PLA plastic because polylactic acid takes a long time to cool down, and the lower layers can deform under the pressure of the layers applied on top if they do not pass the glass transition point.

- In order to avoid shrinkage, it is necessary to eliminate possible drafts. If they occur, the part will cool unevenly, and the shrinkage will occur at different rates, leading to a skewed model. Negative effects can be avoided by purchasing a printer with a closed chamber or by isolating the room in which the device is located, tightly closing the doors and windows. In this case, the model should cool quickly and evenly, so printers are equipped with additional fans installed on the extruders.

- Lower the printing temperature. The optimal setting is to set a temperature only slightly higher than the glass transition temperature of the plastic used. In this case, extrusion will occur correctly, and the layers will quickly fuse together. Excess temperature leads to an increase in cooling time, and therefore the probability of excessive shrinkage of the product.

- Reduce the print density. The optimal choice is to print a model that will be filled inside with a grid or cells made of plastic threads. This option is the most profitable because in this case, not only the material consumption is reduced, but also the risk of deformation due to the sufficient rigidity of the structure and the relatively small amount of plastic in the top layers, which minimizes the pressure created.

Printing errors and how to avoid them

When printing with PLA plastic, errors can occur that will ultimately lead to shrinkage of the finished product.

The most common ones are:

- Insufficient adhesion of the first layer of the product. If this indicator is insufficient, the model may shift due to the first layers peeling off the surface of the heated table. To solve the problem, you can increase the temperature of the platform heating or cover the table with a special compound or film that will mechanically increase adhesion. Polyamide film, aerosol glue, PLA and solvent suspension, as well as regular hairspray and glue pencil, have proven themselves to be good. It is also recommended to increase the contact area of the part with the surface at the development stage of the 3D model by adding a raft - an expanded first layer.

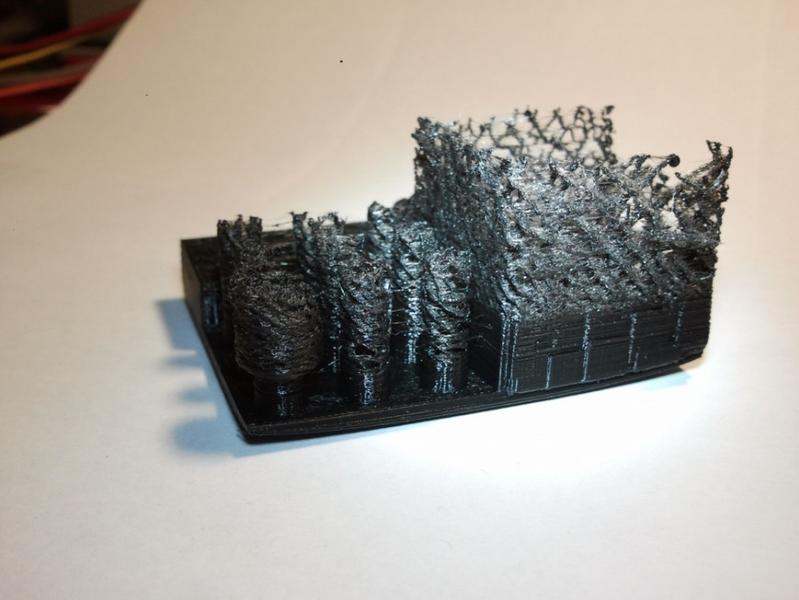

- Appearance of strings, fuzziness, cobwebs. The effect occurs when the material does not correspond to the temperature settings of the printer. It is recommended to lower the extruder temperature and use the retraction function - retraction of the thread in the opposite direction in case of extruder head jamming.

- Deformation of the product. Shrinkage in this case occurs because the printed layers do not have time to harden and cool completely. In order to avoid this phenomenon, it is necessary to reduce the printing speed and lower the plastic heating temperature. It is also recommended to adjust the airflow in such a way that the supplied air does not reach the extruder.

- Excessive shrinkage may also occur when incorrect layer thickness and part filling percentage settings are set. When problems occur, it is recommended to change these parameters in accordance with the manufacturer's requirements.

PLA plastic is a material widely used in 3D printing. It is convenient to use, and products printed with this filament have high performance characteristics. However, printing with this plastic implies compliance with a number of requirements for temperature regime and printing speed. Failure to comply with these rules may result in the deformation of the product.