Detailed instructions for calibrating various parts of the 3D printer

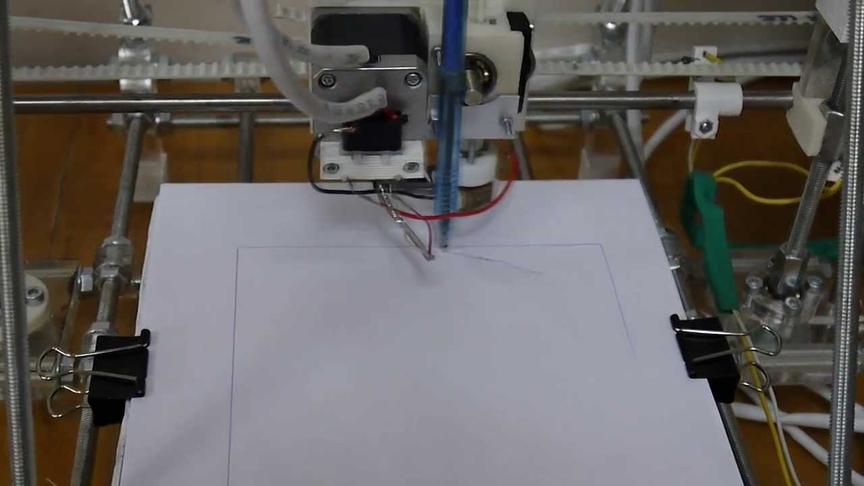

For stable operation of the 3D printer and obtaining high-quality prints, the user needs to periodically calibrate the device. Let's take a detailed look at how to calibrate the axes of the 3D printer, the temperature of the bed, the stepper motors, and the hotend. We will also familiarize ourselves with how to check the accuracy of calibration and avoid errors during the process.

- Calibration of the 3D printer

- Step-by-step instructions for setting and calibrating axes

- Step-by-step instructions for calibrating the bed temperature

- Stepper motor calibration

- Hotend calibration

- Calibration boat

- Errors and ways to avoid them

- What will happen if the 3D printer is not calibrated?

Calibration of the 3D printer

Calibration is one of the ways to adjust the 3D printer, which allows you to eliminate visible printing defects and ensure the creation of the highest quality products.

It is recommended to calibrate the 3D printer in the following cases:

- Immediately after purchasing the printer, before its first use;

- When changing the filament;

- If the print quality has deteriorated or any defects have appeared;

- In case of sudden fluctuations in the temperature of the bed.

Step-by-step instructions for adjusting and calibrating axes

We will consider the main stages of calibrating the axes of the 3D printer using the Marlin firmware as an example. Since conducting this procedure requires only making certain changes to the firmware code.

The sequence of actions during the axis calibration will be as follows:

- In the Arduino IDE, launch the Marlin firmware and open the configuration.h file. In it, find the line #define DEFAULT_AXIS_STEPS_PER_UNIT {78.7402,78.7402,200*8/3,760*1.1}. The numbers in the brackets are the variables of the axes. They are indicated in the following order {X-step,Y-step,Z-step,E-step}.

Reference. Arduino IDE is an open-source environment for developing firmware and uploading it to the memory of the 3D printer microcontroller. This program is free and can be found freely available on the internet.

- The calculation for Z-axis calibration is performed first. The Z-step variable is filled in with the number of motor steps required to move 1 mm. To calculate this parameter, you need to find the number of motor steps per full revolution (it will be 3200 steps) and the pitch of the specific lead screw (for example, an M6 lead screw has a 1 mm pitch, while an M8 lead screw will have a pitch of 1.25). After obtaining the necessary data, you can calculate the number of motor steps required to move 1 mm. To do this, divide the number of motor steps by the lead screw pitch: 3200 / 1.25 = 2560.

- Next, calculations are done for the X and Y axis calibration. If the same belts and the same pulleys are used for both axes, the calibration calculations will look identical. If the parameters of the belts and pulleys differ, individual calculations will be required for each axis. But regardless of the input data, the calculations are always performed according to the same formula: number of motor steps per full revolution / (belt pitch × number of teeth on the pulley). The belt pitch is measured in mm. It indicates the distance between the belt teeth. Usually, the belt pitch parameters can be found by looking at its markings. The number of teeth is calculated manually. As a result, the calculation is as follows: 3200 / (5 × 8) = 80, where 5 is a 5 mm pitch between the teeth of the T5 belt, and 8 is the number of teeth on the belt.

- Calculations are performed for the E axis (extruder calibration data). In order to calculate them, the nozzle must first be heated to the working temperature (for us, it is 80 °C) and extrude a filament of length 100 or 200 mm (your choice). After the filament has come out completely, it is necessary to measure its length. For example, instead of 100 mm, we got 90. Calculating proportionally 90 — 80; 100 — E. The following calculation is obtained: E = 100 × 80 / 90 = 88.9.

- Having calculated all the necessary parameters for calibrating the 3D printer, we enter them into the Marlin firmware in the form of the following line: #define DEFAULT_AXIS_STEPS_PER_UNIT {80,80,3200,88,9}.

- Then the printer board needs to be flashed with the new data and a test sample printed. If the print quality has normalized, then the axis calibration is completed. If there are any deviations, the parameters are adjusted experimentally to the desired values.

Step-by-step instructions for calibrating the bed temperature

Calibrating the 3D printer bed temperature needs to be done under conditions as close as possible to printing conditions (if there is a housing, the printer door is closed, and a cover is put on). This procedure is performed using the PID controller, which allows you to set and maintain a stable bed temperature during operation.

To configure the PID, we use the Marlin firmware, in which the PIDTEMPBED parameter in the "Firmware" section on the "Bed" tab is activated. With its help, the printer is flashed and the main calibration steps are taken:

- In the printer terminal, give the command M303 E-1 ST C№, where E-1 is the bed calibration command; T is the most frequently used printing temperature; № is the number of test process repetitions (from 3 to 7). As a result, the completed command will look like this: M303 E-1 S80 C7.

After the test is done, the printer will display a message on the screen with the three necessary input signal values (Kp, Ki, Kd):

- #define DEFAULT_bedKp 52,60;

- #define DEFAULT_bedKi 6,63;

- #define DEFAULT_bedKd 277,98.

The three numbers obtained are saved in EEPROM or entered into the Marlin firmware. In the first case, you must give two commands in the printer terminal: M502 and M500, in the second case — in the "Firmware" section, in the Configuration.h file, enter the values in the following form:

- #define DEFAULT_Kp 52,60;

- #define DEFAULT_Ki 6,63;

- #define DEFAULT_Kd 277,98.

Attention! Printer calibration is a lengthy process that directly depends on the number of repetitions set. Therefore, if the printer hangs in one place, there is no need to turn it off or try to reboot the 3D printer at that time. You just need to wait for the process to finish.

Stepper motor calibration

The extruder is called the stepper motor in a 3D printer, as it is responsible for the amount of plastic that is extruded per one motor step. For high-quality printing, it is important that the extruder extrudes the necessary amount of plastic specified in our G-code. Therefore, the stepper motor requires periodic calibration. It is performed in the following sequence:

- Checking the operation of mechanical components. First, the idler roller is adjusted and the wear of the extrusion rod gear is checked.

- Adjusting the amount of filament fed by the extruder. The guiding tube is removed from the extruder, and the end of the wire is cut off. Then the protection against starting the extruder with a cold hotend is disabled. For this, the command M302 P1 is executed. The printer is connected to the computer, and the Repetier Host slicer is launched. With its help, G-code with the command "extrude 100 mm of plastic at a speed of 200 mm per minute" is sent. It will look like this: G01 F200 E100.

- Adjusting the stepper motor setting. This is done if the length of the rod is less than desired. To adjust, you need to calculate the desired value using the formula Y × L / l, where Y is the value set in the printer firmware, which can be found by running the M502 command (95.5); L is the length of the rod that was set (100 mm); l is the length to which the filament was actually extruded (for example, 98 mm). After the calculations, a value of 95.5 × 100 / 98 = 97.4 mm was obtained. This value needs to be entered in the printer parameter menu called Estepps/mm. After that, the command M500 is run to save the value in the memory. Calibration is now completed.

Hotend calibration

Hotend calibration is performed similarly to the calibration of the 3D printer bed:

- In the Marlin firmware, the PIDTEMPBED parameter in the "Firmware" section on the "Bed" tab is activated.

- The hotend is moved to the center of the bed and the fan is turned on.

- In the printer terminal, give the command M303 E-# ST C№, where # is the ordinal number of the hotend (if there is only one, then put the number 0); T is the most frequently used printing temperature; № is the number of repetitions of the testing process (from 3 to 7). As a result, the filled command will look like this: M303 Е-0 S240 C7.

- After the test is completed, the printer will display a message on the screen with the three necessary input signal values (Kp, Ki, Kd):

- #define DEFAULT_bedKp 10,71;

- #define DEFAULT_bedKi 0,61;

- #define DEFAULT_bedKd 47,22.

- The three obtained numbers are saved in EEPROM or entered into the Marlin firmware. In the first case, you must give two commands in the printer terminal: M502 and M500, in the second case — in the "Firmware" section, in the Configuration.h file, enter the values in the following form:

- #define DEFAULT_Kp 10,71;

- #define DEFAULT_Ki 0,61;

- #define DEFAULT_Kd 47,22.

Calibration boat

A calibration boat is an STL file of complex structure used to check the correctness of the calibration process.

This product contains a large number of openings of different shapes and diameters, as well as overhangs at various angles. Thanks to such a complex structure of the boat, the user can see how accurately the calibration was performed and how accurately the printer transmitted the sizes and shape of the object.

Errors and ways to avoid them

Here are the most common errors made by users during the calibration of the 3D printer:

- Resetting calibration settings when restarting the printer. The problem arises because the changes were not saved in the EEPROM. Therefore, after entering the data, it is necessary to simply save them by running the G-code M500.

- Printing defects after calibration. Correctly performed adjustment, on the contrary, should not allow printing defects to occur. And this means that the process was not carried out correctly. Here are some reasons that could have spoiled the calibration process:

- Placing the printer on an uneven surface.

- Incorrect assembly of the Y or E axis.

- Blocking the movement of the X, Y and Z axes. To prevent this, go to the Settings menu on the Move axis tab and move all axes in different directions to make sure nothing is obstructing their movement.

- Incorrect placement of the P.I.N.D.A. sensor. For correct calibration, it should be in the Auto home position, i.e. positioned in the center of the lower left calibration point. Also, it is important to position the sensor 1 mm above the tip of the nozzle.

- Insufficient belt tension. For proper calibration, the belts must be tightly tensioned. This parameter can be checked in the printer menu on the Belt Status tab. It should be in the range of 200–280.

What will happen if the 3D printer is not calibrated?

An uncalibrated 3D printer has significant deviations of the bed from the specified level, as well as varying distances between the extruder nozzle and the print bed at different points. Such discrepancies can lead to deformation of the print during printing, clogging of the extruder, and possible printer damage.

To prevent problems in the operation of the 3D printer and ensure the printing of quality products, it is important for the user to regularly calibrate the printer. Moreover, most modern models are equipped with detailed instructions that allow the process to be carried out effectively. However, it is important to remember that calibration is a time-consuming procedure and needs to be conducted carefully and regularly. Only in this case will the stable operation of the printer be ensured.