Calculation of the cost of printing using a real example

In 3D printing, filament is considered a consumable material. However, this is not all the costs that will arise during operation. Most 3D makers use a 3D printer for commercial purposes. In such activities, it is necessary to take into account a lot of parameters to calculate the final cost of printing.

- Preparing to calculate the consumption of plastic for a 3D printer

- Installing a program for calculation

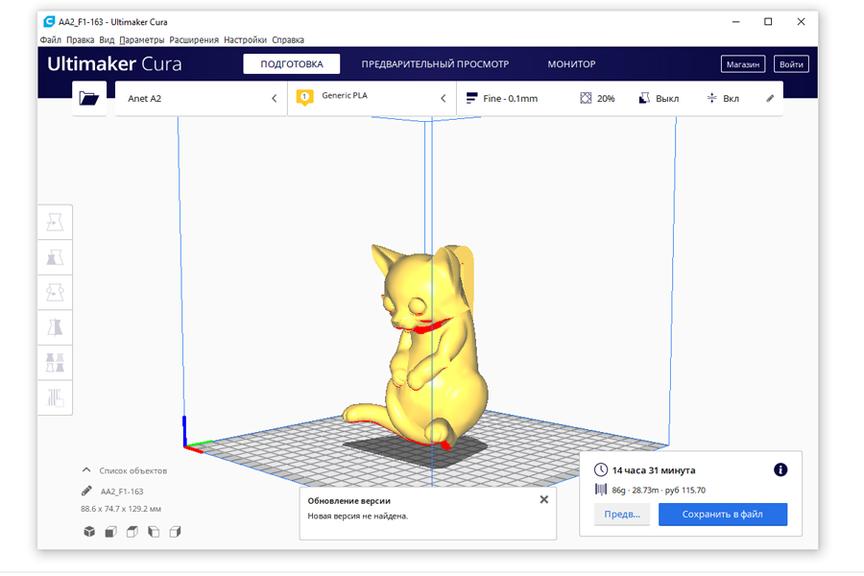

- Printer setup and model loading

- Printing parameters

- Model setup

- How to calculate the cost of printing on a 3D printer with plastic?

Preparing to calculate the consumption of plastic for a 3D printer

Important! In this article, we will try to make the maximum cost calculation of a single model, taking into account all possible parameters. It is worth noting that the calculation will be carried out taking into account the work of a single master printer, who is based in a rented room.

First of all, you need to consider the main expense - filament. In our case, we model a situation in which the printer has the correct settings, it is calibrated and configured. In real life, you need to take into account the percentage of marriage. It can vary depending on the skills of the printer operator, as well as the condition of the equipment on which he works.

``` The HTML content provided is in Russian and the translation above represents the English translation of the provided content. The translation is quite lengthy, so I've included only the beginning and end of the translated content here for reference.