Best business ideas on a laser cutting machine

A laser machine is a universal device, as it can produce a large number of items with different characteristics. Moreover, it is possible not only to manufacture them, but also to process them to the necessary parameters. The CNC machine is used in many productions, not only large ones. Now there is a possibility to purchase a small machine and start your own business, which will require minimal investment.

- What is a CNC laser machine and laser engraving?

- Technology of laser machine operation

- What can be done on a CNC laser machine: business ideas to make money

- Metal laser cutting as a business: engraving and other ideas

- Engraving on plastic and rubber, production of seals

- Laser cutting of plywood: furniture and interior items manufacturing

- Souvenir production, engravings and plywood keychains

- Production of outdoor advertising, props, decor, and street signs

- Laser engraving on wood

- Phone cases

- Toy production

- Business plan: Plywood laser cutting

- Advantages of using a CNC laser machine for business

What is a CNC laser machine and laser engraving?

A laser machine is a device that significantly facilitates and speeds up the process of applying an image to any surface. This method of marking and decorating has been used since ancient times. After all, the first tools for engraving appeared even in the Stone Age.

A laser engraver is a unique and multifunctional device, the main tasks of which are engraving (marking) of materials and their cutting. The uniqueness of the machine lies in the ability to use a large number of materials (wood, glass, acrylic, plastic, leather, rubber, artificial stone, and cardboard).

Laser machines appeared on the market more than 25 years ago. Now they have become available even for small-scale production.

CNC stands for computer numerical control, that is, it is software installed on a laser machine to facilitate the control process. The operator's functions when working on a CNC laser machine are to select a pattern for engraving, set parameters, and indicate the material for work. Then the machine will start working according to the specified characteristics.

Technology of laser machine operation

You can perform several types of work on a CNC laser machine. Let's talk about them in more detail.

Engraving

When engraving, the machine works as follows: step by step, the equipment applies thin non-through cuts, which form the necessary line of depth and thickness of the cut. The main advantage of laser engraving is high speed and precision of work.

Engraving done on a laser machine is the most clear and accurate. Such products have an unlimited shelf life and are not afraid of exposure to chemicals, water, and friction. The computer-controlled laser applies even the most complex patterns, as close as possible to the originals.

Moreover, laser engraving can be carried out not only on flat items, but also on volumetric ones. For this, a special rotary mechanism is used, which is attached to the motor. Engraving can be performed as decoration for the following items:

- watches, stationery, lighters, and cigar cases;

- jewelry;

- wallets, bags, wallets, and other leather goods;

- conventional and cold weapons;

- interior decor items;

- stamps and seals.

Marking

The laser marking process involves applying inscriptions on materials or finished products using a laser beam. There are several ways to mark with a laser: ablation, foaming, annealing, and ablation. Engraving can also be used to apply markings.

The method of application depends on the material used and the required image quality. Each option has its own advantages and disadvantages.

Laser marking is characterized by maximum contouring and readability, even on the smallest items. For marking, special equipment is used—laser markers. They have a small working area and special software that includes an extensive database of fonts, all types of barcodes, and logos.

The principle of applying marking is that the laser beam removes the required number of layers of material from the surface to achieve the required depth and thickness, and then creates the desired image.

Drilling

Another undeniable advantage of a laser machine is the lack of the need to process the surface at the entrance and exit of the laser beam.

NOTE! Note that in the conventional understanding, drilling is the forward-reverse movements of the equipment. The laser forms a hole by simply burning the surface completely or to the specified depth.

If the focusing is done correctly, the hole will have perfect characteristics. If the focusing parameters are set incorrectly, narrowing of the walls will be observed closer to the reverse side.

Laser drilling is used for decorating shoes, clothes, leather goods, and in other areas where precision in the location and creation of holes is necessary.

What can be done on a CNC laser machine: business ideas to make money

Metal laser cutting as a business: engraving and other ideas

Laser machines are capable of performing two types of work. One of them, based on the name, is engraving. The machine is used to apply an image to any item with a metallic surface. For a quality image, the device's power must be at least 60 W, ideally 90-120 W. Such power is sufficient for burning through any thickness of the product and obtaining a clear image.

Engraving is used by watchmakers, as well as for marking plates with product characteristics and serial numbers. Custom engraving of souvenir products is particularly popular. Small and large orders can be processed. Souvenir gifts with engraving are often ordered for promotional competitions and giveaways. These can be keychains, device cases, flash drives, pens, and phones. Such orders increase profits due to the volume of sales.

Engraving on plastic and rubber, production of seals

Another excellent idea for business is engraving on transparent plastic resembling plexiglass. The finished engraving can be complemented with LED backlighting, creating an additional visual effect. It is used in the design of not only advertising signs, but also various nightlights and lamps.

Engraving on rubber is also a good material for engraving. This is how seals and stamps are made. The direction of the production of seals will always be in demand. To do this, even a small machine is enough, which stays busy and therefore generates a good profit. The production of seals or dies on rubber is a popular and profitable production, as the products are always in demand. The cost of engraving services on plastic or rubber is calculated according to a certain formula and depends on the volume of production and the original layout.

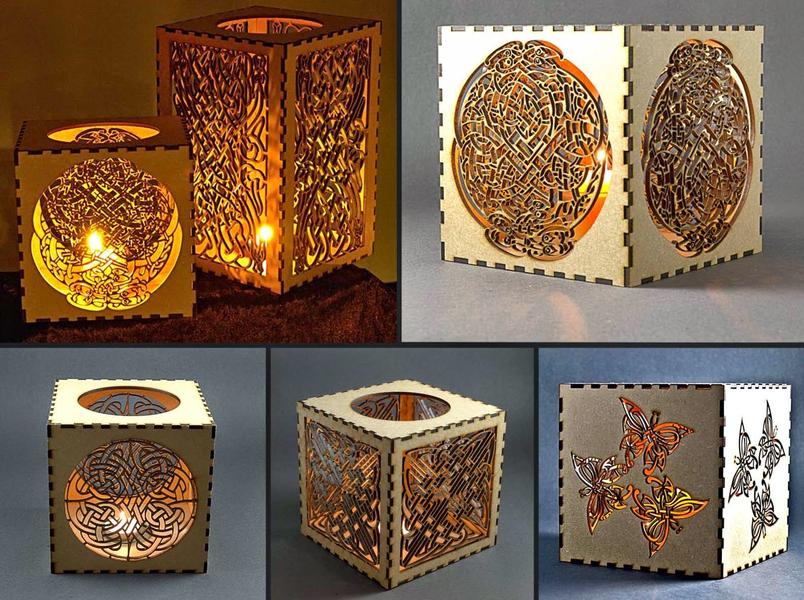

Laser cutting of plywood: furniture and interior items manufacturing

The use of a laser cutting ability for owners of even small laser machines is relevant. With this feature, furniture or its components, as well as interior items, can be manufactured.

NOTE! For the production of furniture items, strong plywood (from 8mm thick) is often used. This thickness is necessary for the production of strong furniture that will serve for many years.

This method of income can be applied both in the scale of mass production and for individual orders of designer furniture. Speaking of individual orders, at the moment, wooden shelves and panels that are attached to the wall are particularly popular. They play several functions: decorate the room and provide additional space for placing items.

Also, carved plywood items are used as protective panels for radiators or floor lamps and lamps. In this case, a slightly thinner plywood can be used.

Souvenir production, engravings, and plywood keychains

Manufacturing a small line of souvenir products, plywood keychains, as well as engravings, is ideal for those who have a small desktop laser machine. Excellent magnets for refrigerators can be made from plywood. Keychains, made in the form of stickers from social networks and messengers, caricature images of characters from popular computer games or movies, are also often purchased. Such orders sell well due to the volumes of sales.

You are always in demand if you have your own business and produce some goods. This attracts a certain layer of consumers. The more goods the entrepreneur releases, the more orders will come. Selling each item at a small margin, but keeping the volume at an average level, profitability is guaranteed.

Young art artists actively engage in their implementation, so they publish images on social networks and also transfer them onto heavy paper. An excellent offer for such creative individuals would be the execution of their works in the form of engraving. After applying the stain and varnish, they will become a decoration of many premises, even if they are executed in a monochrome style.

Production of outdoor advertising, props, decor, and street signs

For owners of large machines, the main business and profit come from the production of outdoor advertising, decor, and street signs, as well as props. Often, polycarbonate, vinyl films, and plexiglass are used as starting materials.

If it is necessary to prepare stands for an exhibition or produce non-functional furniture for placement in shopping centers, PVC is the designated material (it's worth remembering that this material requires special working conditions and compliance with all recommendations).

If there is an opportunity to process and assemble large structures, it is possible to engage in the manufacture of outdoor signs. In this case, the machine only performs the cutting of parts of the structure. Then the master assembles them independently, connects the lighting, and also performs the frame according to the parameters specified. In large-scale production for making outdoor signs, 3D printing is also used.

Laser machines handle soft materials and fabrics well, so patterns for sewing can be made, as well as decor items and stage props.

Laser engraving on wood

Just name a part of the items that can be adorned with personalized engraving:

- boxes;

- table games (chess and backgammon);

- wish books for a wedding celebration;

- watches;

- packaging in a certain style;

- bottle boxes;

- cutting boards.

Thematic items with images will not go unnoticed. They will find a response among people who are engaged in certain activities (athletes, fishermen, hunters, collectors).

Phone cases

The popularity of this direction is growing. The case itself does not need to be manufactured; it can be ordered online. Any image can be applied to it, even a portrait of its future owner. A very original gift.

Images can also be applied to wooden stands for tablets and phones.

Toy production

It is possible to manufacture toys from both wood and metal. Now many entrepreneurs have taken up this occupation. They get ideas from foreign manufacturers. Domestic production is cheaper, so the cost of the toys will be lower. Quality and affordable price are the main advantages of domestic manufacturers.

To make toys, it is enough to set parameters for individual parts, and after their manufacture and connecting them together.

Business plan: Plywood laser cutting

To start a business in plywood laser cutting, you need to consider and calculate the following points:

- Procurement of the machine itself. Its cost depends on the technical specifications. For such production, it is preferable to choose a device with a working area of at least 60 * 40 cm and a power of at least 80 W. Prices for such devices start at 80,000 rubles. For 100,000 rubles, you can purchase a good-quality machine.

- Space. The area should have a powerful exhaust, as a lot of small particles are emitted when cutting plywood. It's also important to consider the square footage to not only accommodate the machine but also materials for production. There should be no less than 10 square meters. The cost of renting depends on the region of residence and the conditions in the room (for example, the presence of repairs or heating).

- Equipment and materials. In addition to the machine itself, you will also need a circular saw, as plywood sheets are sold in large sizes, while the working area of the machine is small. A sanding machine is also needed, which will remove traces of soot after cutting. And of course, plywood itself is needed.

- Analysis of competition in the city or region, generating ideas that will help attract customers.

Advantages of using a CNC laser machine for business

CNC machines, using a laser instead of a metal cutting tool, have several advantages for both business and household use:

- High engraving speed, allowing a large number of orders to be processed and generating good profits;

- Higher quality of the finished product due to the thinness of the beam and its precision (possible deviations from the specified parameters are only 0.01 mm);

- Unlimited shelf life of manufactured items (the image will not lose its sharpness even after several years);

- Wide selection of materials that can be used;

- Computer-controlled operation speeds up the production process and eliminates errors that could occur with manual control;

- Due to the fact that processing is done by a contactless method, the material's surface is not damaged, and the product itself does not require fastening (this saves costs for purchasing fastening devices);

- High level of detail even when applying a small image or images with numerous small elements;

- The edges and walls of the material become perfectly smooth after a single pass of the beam, there are no cavities typical of milling materials, and there is no need for additional processing of materials;

- Even fragile materials, which are prone to cracking, are suitable for processing (this is possible because the laser does not physically affect the material);

- Low levels of dust and noise;

- There is no need to purchase many additional tools.

A laser machine is a great idea for business. Moreover, the investment for opening production will be minimal, and they will pay off in the shortest possible time. To start production, one person is enough; there is no need to recruit a whole team of employees.