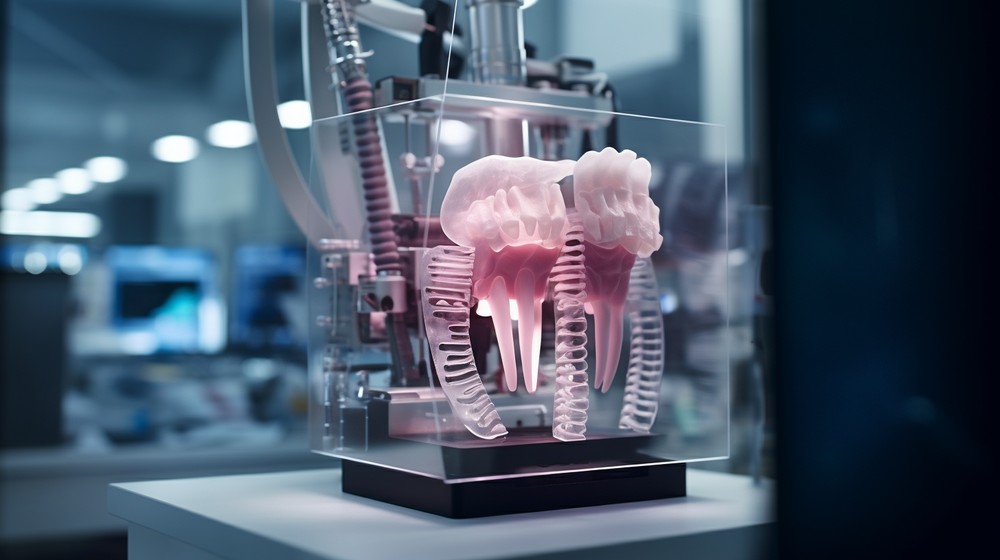

3D printing of teeth: The future of dental technology

The field of dentistry is constantly evolving, and 3D printing technology is at the forefront of this revolution. 3D printing of teeth not only demonstrates a multitude of advantages for both dentists and patients, but it also expands the boundaries of what is achievable in dentistry. The aim of this article is to shed light on this remarkable technology, explore its nuances, areas of application, and positive impact on the dental industry.

Contents:

- Genesis of 3D Printing in Dentistry

- Understanding the Technology Behind 3D Printing of Teeth

- Advantages of 3D Printing in Dentistry

- Application of 3D Printing in Dental Practice

- Patient Experience

- Legal and Ethical Aspects

- Questions and Answers

- Conclusion

Genesis of 3D Printing in Dentistry

The emergence of 3D printing in dentistry marked an important milestone, bridging the gap between traditional practice and modern technological advancements. This section discusses the evolution, establishment, and challenges encountered in the initial stages of integrating 3D printing technology into dental practice.

Historical Evolution

The history of 3D printing, also known as additive manufacturing, began in the 1980s. However, in dentistry, it started being used in the early 2000s. Initially, 3D printing was used to create dental implants and orthodontic devices on a small scale. Over time, as the technology improved, it began to be used in other areas of dentistry, including making crowns, bridges, dentures, and even orthodontic appliances. The evolution of 3D printing technology was driven by a constant pursuit of accuracy, efficiency, and cost-effectiveness in dental procedures.

Emergence of 3D Printing for Teeth

3D printing of teeth became a revolutionary solution to many problems faced by traditional dental practices. Thanks to the ability to create accurate, individual dental devices and restorations, 3D printing technology significantly reduced the time and costs associated with dental procedures. Additionally, the emergence of biocompatible materials suitable for 3D printing further promoted the use of this technology in dental practice. Digital precision and the ability to adapt dental solutions to individual patient needs made 3D printing an indispensable tool in modern dentistry.

Challenges in the Early Stages of Development

Despite the enormous advantages offered by 3D printing technology, its integration into dental practice did not come without difficulties. These challenges included:

High Costs: The initial investments required for purchasing 3D printers and corresponding software were significant, making it a serious financial commitment for many dental clinics.

Technical Expertise: Operating 3D printers and designing dental prosthetics required a certain level of technical knowledge, necessitating additional training and education.

Material Limitations: Initially, there were limited biocompatible and suitable materials available for 3D printing in dentistry.

Regulatory Compliance: Ensuring compliance with strict regulatory standards of the dental industry was another challenge faced by practitioners in the early stages of implementation.

Patient Acceptance: Convincing patients of the need for 3D printing over traditional methods was also challenging due to unfamiliarity with the new technology.

Overcoming these challenges required concerted efforts from practicing dentists, technology developers, and regulatory bodies. Joint efforts paved the way for the widespread application of 3D printing technology in modern dentistry, ensuring a more efficient, accurate, and patient-friendly approach to dental treatment.

Understanding the Technology Behind 3D Printing of Teeth

Familiarizing oneself with the field of 3D printing in dentistry reveals a fascinating combination of innovative technologies and precise craftsmanship. The goal of this section is to talk about the basic principles, various types of 3D printers, and materials used in the process of 3D printing of teeth, and to provide insight into the technical expertise that contributes to the development of modern dental practices.

Basic Principles

The essence of 3D printing of teeth lies in additive manufacturing - a process of layer-by-layer creation of objects based on digital models. Here is a simplified diagram of this process:

Digital Modeling: Everything starts with creating a digital model of the dental object, be it a crown, a bridge prosthesis, or a dental implant. This is usually done using Computer-Aided Design (CAD) software, into which precise measurements and design specifications are entered to create a virtual model.

Slicing: Once the digital model is ready, it is sliced into many thin layers using slicing software. This software also generates the necessary support structures and calculates the optimal printing trajectory to ensure accuracy and strength of the final object.

Printing: Then the actual printing process begins, during which the 3D printer applies the material layer by layer according to the sliced model. The material is usually in liquid or powder form and hardens using various methods, such as UV curing or laser sintering.

Post-processing: After printing, the object undergoes post-processing to remove support structures, smooth surfaces, and achieve the required finish.

Types of 3D Printers Used in Dentistry

Various types of 3D printers are used in dentistry, each with its unique capabilities:

Stereolithography (SLA): SLA printers use a laser to cure liquid resin into solid plastic. They are known for their high precision and are often used to create complex dental objects such as crowns and bridges.

Digital Light Processing (DLP): Similar to SLA, DLP printers use a digital light projector to cure the resin. They work faster than SLA printers because they cure an entire layer of resin at once.

Selective Laser Sintering (SLS): SLS printers use a laser to sinter powder materials layer by layer. They are suitable for creating durable and complex structures.

Fused Deposition Modeling (FDM): Although less common in dentistry, FDM printers melt and extrude thermoplastic filament, creating objects layer by layer.

Materials Used in 3D Printing of Teeth

The choice of materials is crucial for ensuring the functionality and biocompatibility of 3D-printed dental objects. The most widely used materials include:

Resins: Biocompatible resins are widely used due to their ability to achieve high precision and good surface quality. They are suitable for manufacturing various dental structures, including crowns, bridge prostheses, and orthodontic devices.

Ceramics: Dental ceramics are used for their aesthetic appearance and high strength. They can mimic the appearance of natural teeth, making them a preferred choice for restorations.

Metals: Metals such as titanium and cobalt-chrome alloys are used for their strength and durability in manufacturing dental implants and other structural dental constructions.

Polymers: Polymers like polyetheretherketone (PEEK) are known for their lightness and biocompatibility, making them suitable for some dental applications.

This comprehensive understanding of technology, various printers, and materials gives a clear picture of the extensive foundation upon which dental 3D printing is built. Thanks to ongoing innovations in these areas, 3D printing technology can lead the dental industry to an era of unprecedented precision, efficiency, and patient satisfaction.

Benefits of 3D Printing in Dentistry

The introduction of 3D printing technology in dental practice heralds a new era of improved service quality and patient satisfaction. The paradigm shift brought about by the use of 3D printing in dentistry has significantly impacted various aspects of dental care delivery. This section will examine some of the main benefits of 3D printing in dentistry, including precision and accuracy, cost-effectiveness, and accelerated procedures.

Precision and Accuracy

3D printing has enabled an unprecedented level of precision and accuracy in dental procedures. Here's how:

Digital Impressions: Unlike traditional molds, which can be uncomfortable for patients and may not be sufficiently accurate, digital impressions used in 3D printing are highly precise and can capture the finest details of the oral cavity.

Customization: 3D printing allows for the manufacture of dental prostheses and restorations according to the unique anatomical features of each patient. This level of individualization ensures a better fit and functioning of dental implants, crowns, and other restorative devices.

Reduction of Human Errors: Traditional dental practice often involves manual processes, which are prone to human errors. As a digital technology, 3D printing minimizes such errors, ensuring a higher level of accuracy in the final products.

Cost Effectiveness

The cost effectiveness of 3D printing is an advantage for both practicing dentists and patients.

Material Use Efficiency: 3D printing is known for its efficiency, as only the necessary amount of material is used to create dental devices, reducing waste.

Labor Costs: The automation of the 3D printing process reduces labor costs, thereby lowering the overall cost of producing dental devices and restorations.

Reduced Procedure Costs: By speeding up the process and reducing the number of necessary appointments, 3D printing can significantly reduce the cost of procedures, making dental care more affordable.

Accelerated Procedures

In dentistry, time is of the essence, and 3D printing significantly speeds up various dental procedures.

Rapid Fabrication: Traditional methods of creating dental devices and restorations can be time-consuming. In contrast, 3D printing allows for their rapid production.

Same-Day Restorations: 3D printing enables the design, creation, and installation of dental prostheses, such as crowns and bridges, in a single appointment, saving significant time for both the dentist and the patient.

Workflow Optimization: The digital workflow associated with 3D printing simplifies the process from diagnosis to treatment, speeding up turnaround times and improving service efficiency.

Application of 3D Printing in Dental Practice

3D printing has become a transformative technology in dentistry, offering innovative solutions and complementing various dental procedures. This section highlights the multifaceted applications of 3D printing in dental practice: from the creation of dental implants and orthodontic devices to the manufacturing of temporary crowns and bridge prostheses.

Creation of Dental Implants

3D printing has revolutionized the field of dental implants, allowing for:

Individualization: Each dental implant can be manufactured considering the exact dimensions and features of the patient's teeth anatomy, ensuring precise fitting and increased comfort.

Versatility of Materials: 3D printing allows the use of various biocompatible materials, which can be chosen depending on the requirements of the dental implant, whether it's strength, durability, or aesthetic appeal.

Efficient Production: The organized digital workflow of 3D printing speeds up the production of dental implants, reducing patient waiting times.

Orthodontic Devices

The manufacturing of orthodontic devices has been significantly optimized thanks to 3D printing technology:

Precision Fabrication: The high resolution and accuracy of 3D printing allow for the creation of orthodontic devices that provide the required corrective forces with high precision.

Accelerated Production: The capabilities of 3D printing allow for the rapid production of orthodontic devices, shortening manufacturing times and ensuring timely treatment.

Cost Efficiency: Efficient use of materials and automation of the manufacturing process lead to reduced costs, which can be passed on to patients.

Temporary Crowns and Bridge Prostheses

3D printing has also found wide application in the creation of temporary crowns and bridge prostheses:

Immediate Manufacturing: 3D printing technology allows for the manufacturing and installation of temporary crowns and bridge prostheses in a single appointment, improving patient care quality.

Aesthetic Accuracy: With 3D printing, temporary restorations can be manufactured with high aesthetic accuracy to match the natural appearance of the patient's teeth.

Adaptability of Materials: The range of materials compatible with 3D printing allows for the creation of temporary restorations that are strong, durable, and visually appealing.

3D Printing of Dental Prostheses

The procedural basis of 3D printing in dentistry includes a systematic approach, starting from digital impressions and ending with the actual printing process.

Digital Impression

Non-Invasive Scanning: Digital impressions are taken using intraoral scanners, which are non-invasive and provide comfortable conditions for patients.

High-Resolution Capture: Digital impressions have high resolution, allowing the capture of the smallest details of teeth anatomy, which is very important for the accuracy of subsequent processes.

Restoration Design

Computer-Aided Design (CAD): Digital impressions serve as a blueprint for designing the restoration using CAD software, where the dentist can meticulously design the dental prosthesis, ensuring it meets the required characteristics.

Virtual Prototyping: Before printing, a virtual prototype allows for any necessary adjustments, ensuring a perfect fit of the final product.

Printing Process

Layer-by-Layer Fabrication: The 3D printer fabricates the dental device layer by layer, adhering to the project specifications to ensure precision and accuracy.

Material Curing: Depending on the type of 3D printer and material used, the layers are cured or solidified using various methods, such as UV radiation or laser sintering.

Post-Processing: After printing, the dental device may undergo post-processing to achieve the required cleanliness, ensure biocompatibility, and prepare it for patient use.

The application of 3D printing in dental practice is an example of the synergy of technology and dentistry, contributing to increased precision, patient satisfaction, and overall efficiency. Thanks to the continuous improvement of 3D printing technology, the horizons of what's achievable in dentistry continue to expand, promising a bright future for both practicing dentists and patients.

Patient Experience

3D printing has significantly changed the patient experience in dental practice, creating a more efficient, comfortable, and pleasant journey from diagnosis to treatment. Here's an overview of how 3D printing enhances patient interaction by reducing waiting times, increasing comfort, and ensuring long-term satisfaction.

Reducing Waiting Times

Immediate Fabrication: 3D printing allows for the immediate manufacturing of dental devices and restorations, often within a single appointment. This significantly reduces the waiting time traditionally associated with dental procedures.

Optimized Workflow: The digital workflow associated with 3D printing optimizes the entire process from obtaining digital impressions to the actual printing of dental devices, ensuring faster order completion times.

Rapid Prototyping: 3D printing capabilities allow for quick creation and adjustment of prototypes, ensuring accuracy and readiness for use of the final dental device or restoration in less time.

Increased Comfort

Custom Fit: The ability to create dental devices and restorations considering the unique anatomical features of each patient's teeth ensures a more comfortable fit and better functionality.

Non-Invasive Scanning: Digital scanning for impressions is less invasive and more comfortable for patients compared to traditional impression-taking methods.

Comfortable Materials: 3D printing allows for the use of materials that not only meet functional requirements but also provide comfort to the patient.

Long-Term Satisfaction

Durable Restorations: 3D-printed restorations are known for their strength and durability, contributing to the long-term satisfaction of patients.

Aesthetic Appeal: The precision of 3D printing allows for the creation of aesthetically appealing restorations, enhancing patient confidence and satisfaction.

Cost-Effectiveness: The cost savings associated with 3D printing can also be a factor in long-term satisfaction, as patients receive high-quality dental care at a more affordable price.

Legal and Ethical Aspects

Like any other medical technology, 3D printing in dentistry has its legal and ethical aspects. This section sheds light on the regulatory framework and ethical aspects related to the use of 3D printing in dental practice.

Regulatory Framework

Compliance with Dental Standards: Dentists must ensure that 3D-printed dental devices and restorations comply with established dental standards, guaranteeing safety and effectiveness.

Material Certification: Materials used in 3D printing must be certified for biocompatibility and other necessary standards by the relevant regulatory authorities.

Device Certification: Similarly, devices used in 3D printing must also be certified for use in dental practice, ensuring they meet required safety and performance standards.

Data Confidentiality: Given the digital nature of 3D printing, ensuring the confidentiality and security of patient data is one of the most important regulatory requirements.

Ethical Considerations

Informed Consent: Patients must be adequately informed about the use of 3D printing in their dental care, including any risks and benefits associated with it.

Accessibility: Ethical considerations extend to the accessibility of 3D printing technology, ensuring it does not exacerbate existing inequalities in dental healthcare.

Continuous Education: Dentists are obliged to stay abreast of the latest advancements in 3D printing technology to provide the best quality of medical care.

Environmental Impact: The impact of 3D printing materials and processes on the environment is also an ethical aspect, as is the responsibility for sustainable development.

The emergence of 3D printing in dentistry not only enhances the quality and efficiency of dental care but also brings to the forefront important legal and ethical aspects. Reasonable regulation of these aspects is crucial for using the full potential of 3D printing technology beneficially and fairly for all stakeholders.

FAQs

How Does 3D Printing Compare to Traditional Methods in Dentistry?

3D printing has been a game-changer in dentistry, providing several advantages over traditional methods:

Precision and Accuracy: 3D printing offers higher precision and accuracy in creating dental prostheses and restorations compared to manual methods.

Speed: Digital 3D printing technology significantly speeds up the process, allowing for faster turnaround times, and in some cases, even same-day restorations.

Customization: 3D printing allows for the individualization of dental prostheses according to the unique anatomical features of each patient, ensuring a better fit and functionality.

Cost-Effectiveness: Although initial investments may be higher, efficiency and material savings in 3D printing can lead to reduced costs over time.

Is 3D Printing of Teeth Safe?

Yes, 3D printing of teeth is considered safe when performed by qualified dental professionals using certified materials and equipment:

Biocompatible Materials: Materials used in 3D printing for dentistry are certified for biocompatibility, ensuring their safety for use in the human body.

Sterilization: Post-printing processing of 3D-printed dental devices includes thorough sterilization to ensure the absence of contaminants before placement in the patient's oral cavity.

What Are the Costs of 3D Printing Dental Procedures?

The cost of 3D printing dental procedures can vary depending on several factors:

Material Costs: The type of material used can influence the cost, with some materials being more expensive than others.

Equipment Costs: The cost of equipment for 3D printing and its maintenance can also affect the overall cost.

Labor Costs: Although 3D printing reduces labor costs over time, the required expertise can sometimes lead to higher labor costs initially.

Geographical Location: Costs can also vary depending on geographical location and the cost of living in the region.

How Long Do 3D-Printed Dental Implants Last?

The durability of 3D-printed dental implants can be comparable to traditional implants, and with proper care, they often last many years:

Material Quality: The quality of the material used in 3D printing can significantly affect the longevity of the dental implant.

Proper Fitting: Proper fitting, facilitated by the accuracy of 3D printing, can also contribute to the longevity of the implant.

Maintenance: Like traditional implants, the lifespan of 3D-printed dental implants can be extended with proper oral hygiene and regular dental check-ups.

Can Any Dentist Perform 3D Printing Procedures?

Not necessarily. Performing 3D printing procedures requires:

Specialized Training: Dentists need to undergo specialized training to master the nuances of 3D printing technology, including working with the equipment and designing dental devices.

Equipment: Dental clinics must have the necessary equipment and software for 3D printing.

Certification: Depending on the region, performing 3D printing procedures in dental practice may require certifications or permissions from regulatory bodies.

What are the Limitations of 3D Printing in Dentistry?

Despite its numerous advantages, there are also some limitations to 3D printing:

Initial Investment: The initial investment in equipment and software for 3D printing can be high.

Material Limitations: Despite the expanding range of materials available for 3D printing, there are still some limitations in terms of material properties and biocompatibility.

Technical Challenges: The technical complexity of 3D printing requires ongoing training and skill enhancement to keep up with technological advancements.

Regulatory Barriers: There may be regulatory hurdles, including certifications and approvals, that can slow down the adoption of 3D printing in dental practice.

Conclusion

3D dental printing is a promising direction in dentistry, embodying the essence of technological progress. Despite the challenges that still need to be overcome, the trajectory of development is positive, making the future of dentistry bright and promising.