3D printers for home - overview of the best and reliable models for home.

3D printers are designed for creating volumetric models. Many even acquire these devices for home use as a hobby. It's interesting to watch how a part, the design of which you developed yourself, comes to life. Moreover, such technology is simply essential for jewelers, architects, designers, and dentists. This is why the popularity and demand for printers are growing every year.

How to Choose for Home Use

Before purchasing an adaptive technology device, it is important to consider some nuances to buy a truly high-quality item at a reasonable price.

Printing Technology

The most popular option is the extrusion method. Melted plastic filament is fed through a special hole. Droplets of plastic fall onto the platform and form the necessary shape.

The next technology for home use is stereolithography. In this case, the shape is formed by a laser. It acts on liquid material, causing it to harden in layers.

In another technology, ultraviolet light is used instead of a laser. In this case, the entire detail is affected simultaneously. Ultraviolet works more precisely compared to the previous technologies. However, the cost of liquid material will be much higher.

The latest development slightly differs from the ultraviolet one. The difference is only in the light source. Here a liquid crystal matrix is used, through which a layer of polymer is exposed (this is done thanks to the work of LEDs).

Type of Plastic

In most home printers, layer fusion technology is used. The method consists of creating an image using several horizontal layers. The plastic filament melts and falls into a form for cooling and hardening. For this, plastic wound on a spool is needed.

There are two types of filaments:

- PLA filament. Biodegradable material. It is obtained from corn, beet, or cane sugar. Anyone can work with such materials, even pregnant women and children, as it is non-toxic. But PLA filament has its drawbacks. They are very dependent on climatic indicators. Therefore, the figure often gets spoiled with increased or decreased air temperature. And in general, the models obtained are not durable.

- ABS filament. This type of plastic is presented as a high-impact technical-grade thermoplastic resin. Styrene and butadiene are added to the ABS filament. It is more suitable for experienced users who have mastered the skills of creating volumetric models.

There are other materials for making figures (such as copper, wood, nylon, resin, or stainless steel), but they are installed in more expensive models.

NOTE! There are printers that can create figures from dough. But it is still not recommended to consume such a blank due to poor hygiene of production.

Layer Thickness

This parameter is especially important for those who need precise images and their detail. Reducing the printing resolution (which is the layer thickness) leads to a coarser model. High printing resolution allows for the creation of models with minimal relief and maximum image detail.

To get a quality detail, it is recommended to choose printers with a layer thickness of 80–100 microns. For professional use, a thickness of 200 microns is chosen.

Printing Space

Printing space refers to the useful base area on which a three-dimensional object is created. Increasing this parameter allows for a model that closely resembles the original given image.

NOTE! When choosing, keep in mind that increasing this indicator will also increase the size of the device itself. Before purchasing a printer, you need to think about the free space for it.

Number of Extruders

Standard printers are equipped with a printing head. In a 3D printer, extruders are responsible for heating the plastic and creating a volumetric model. Most home printers are equipped with only one extruder. This means that the device can only work with one material of one color at a time.

There are printers with two extruders. But it is recommended to buy it only if there is a need for fast printing. Such devices are also needed to create figures from two types of plastic or its two shades. But keep in mind that it will not be possible to create a model from many colors. The number of shades is limited to the number of built-in extruders.

Printing Speed

This characteristic depends not only on the number of extruders but also on their design. Moreover, the type of plastic used also affects the printing speed. A standard device extrudes 20 mm of plastic per second.

Since models are created in three-dimensional space, many other factors also influence the speed of creating figures. For example, the number of small details in the figure, as well as the maximum thickness of the plastic filament. In any case, one figurine will be manufactured for at least 3 hours.

However, a novice in 3D should consider this criterion last.

Additional Characteristics

Such parameters include the ability to print figures directly from a memory card. In this case, you do not need to connect the printer to a computer. Also, images can be transferred to the printer via smartphones and wireless communication.

Top Best Models 2021 - 2023

Let's list the best printers for home use.

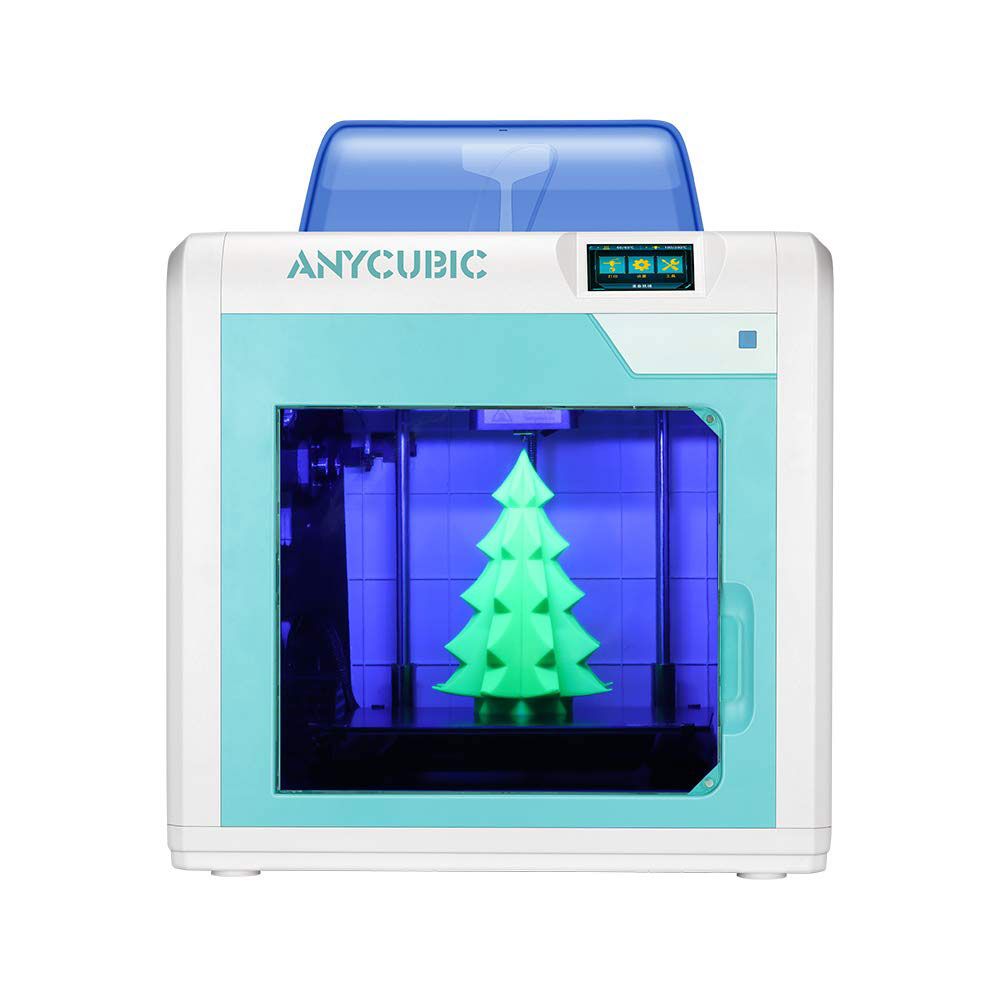

Anycubic 4Max Pro 3D Printer

This is a slightly improved version of the affordable device for home use. It differs in having a fully enclosed case, making it safer and more convenient to work on. The extruder heats up to a maximum of 260 degrees. The nozzle diameter is 0.4 mm.

Advantages:

- Intuitive control;

- Simple construction;

- Operates quietly;

- Attractive design;

- Does not require much space.

Disadvantages:

- Unable to manufacture large parts.

- Maximum Extruder Temperature: 250 °C

- Printing Method: FDM (Fused Deposition Modeling)

- Travel Speed: 100 mm/s

- Print Bed Temperature: 100 °C

- Print Accuracy: XY: 12.5 µm, Z: 0.2 µm

- Build Area: 270x205x205 mm

- Speed: 60 mm/s

- Number of Printing Heads: 1

- Layer Thickness: 50 µm

- Filament Diameter: 1.75 mm

- Nozzle Diameter, mm: 0.4 mm

- Weight, kg: 22.5

3D Printer Wanhao Duplicator i3 Plus Mark II (Di3+ Mark II)

A new model of a compact printer that is quickly gaining popularity among beginners. Features a stylish design and is used at home or in educational organizations. Users note its ease of use. The printer is equipped with a metal extruder, allowing for the creation of high-precision models.

The print surface is honeycomb-patterned for quality adhesion. The surface is removable, making it easy to take off printed parts. The device prints using a layer-by-layer deposition technique. Additionally, the printer can receive images directly from a memory card.

Characterized by an average print speed – 80 mm/sec.

Advantages:

- High-quality printing;

- Affordable price;

- Compact size, allowing it to be placed even on a desk;

- Low power consumption;

- Ideal for beginners in creating 3D models.

Disadvantages:

- High noise level during operation;

- Low level of detail;

- Suitable exclusively for home use.

- Printing: FDM

- Build Volume: 200 X 200 X 180 mm

- Speed: 10-70 mm/s

- Supported Materials: PLA, HDPLA, PETG, TPU, ABS, ASA

- Layer Thickness: 100 µm

- Filament Diameter: 1.75 mm

- Nozzle Diameter, mm: 0.4 mm

Anycubic Photon S

The print layer thickness is 0.1 mm. The main advantage of this model is its compatibility with printing materials from other manufacturers. The body material is durable plastic. However, caution is advised when opening and closing the lid. The printing platform surface is textured, which aids in better holding of the parts.

The screen for photopolymer resin includes backlighting for convenience. The matrix contains a total of 28 LEDs, enhancing print quality. The printer operates from the mains and is turned on by pressing a button located on the side surface.

Also, the device has slots for memory cards. Additionally, the design includes carbon filters for purifying the air from chemical impurities. This allows the printer to be used even in small spaces. The manufacturer has also considered the ability to monitor the printing process through wide viewing windows.

The layer thickness is small – only 10 µm, but figures are produced quickly and at a high resolution of 2560*1440. Control is carried out through a touch panel with sensitive buttons.

The material for manufacturing parts is resin, which results in smooth details that require no further processing.

NOTE! This device is suitable not only for home use but also for dental, jewelry, and design applications.

Advantages:

- Ability to use resin from different manufacturers;

- Fast startup speed;

- Precise printing of details;

- Can print even without connecting to a computer;

- Accessible and understandable control and setup.

Disadvantages:

- Weak fastenings.

- UV Wavelength: 405 nm

- Printing: LCD

- Print Resolution: 2560*1440

- Print Accuracy: XY: 47 µm, Z: 1.25 µm

- Build Volume: 115x65x165 mm

- Speed: 20 mm/h

- Layer Thickness: 25 µm

Anet A8

The model's body is made of metal. The work chamber is open, the table is heated, and an informational display is integrated for control. Anet A8 allows for the insertion of any type of plastic.

The worktable heats up to 100 degrees Celsius, which is sufficient to hold the part firmly without slipping. Printing occurs at a speed of 100 mm/sec. A small workpiece with 2 cm sides takes 2–3 hours to manufacture.

Additional advantages include compatibility with various operating systems. The printer costs only 13–14 thousand rubles. However, at this price, users need to assemble the construction themselves (a novice will need up to 12 hours to assemble and calibrate the device).

Advantages:

- High precision and quality of printing;

- Possibility to upgrade and modify the device;

- Compatible with any type of plastic;

- Heated platform;

- Affordable price;

- Large working area.

Disadvantages:

- Requires self-assembly;

- There may be defects that can only be identified after full assembly.

- Body Material: metal, acrylic

- Printing: FDM

- X and Y Axis Resolution: 12 µm

- Print Bed Temperature: 96°C

- Extruder Temperature: 260°C

- Build Volume: 220x220x240 mm

- Speed: 100 mm/s

- Number of Print Heads: 1

- Supported Materials: PLA; ABS; TPU; PVA; Nylon; PP; Wood

- Layer Thickness: 120 µm

- Filament Diameter: 1.75

- Nozzle Diameter, mm: 0.4

Photopolymer Wanhao Duplicator 8

A more expensive model, costing up to 85,000 rubles. The body is made of dense, high-quality metal. The lid opens conveniently and is securely attached. There's a viewing window to observe the manufacturing process.

At the bottom of the body, there is a screen displaying the model itself, the number of plastic layers, and the remaining time. To prevent the tank from shifting during operation, it needs to be secured with four special bolts.

The design includes two memory card slots. Additionally, it's possible to load original drawings via wireless communication. The device has a carbon filter for air purification, which is easily removable and cleanable. The construction weighs 22 kg. A medium-sized model is manufactured in 3-4 hours.

NOTE! This model is suitable for those who need highly accurate details, such as architects, designers, dentists, and jewelers.

Advantages:

- Rich equipment set;

- Wide working surface;

- Touch sensor control;

- Possibility of wireless connection;

- High precision of finished parts.

Disadvantages:

- High cost;

- Expensive polymers.

- Body Material: steel

- Weight, kg: 22

- UV Wavelength: 405 nm

- Printing: DLP

- X, Y Axis Precision, mm: X/Y: 0.075 mm, Z: 0.035~0.1 mm

- Build Volume: 190 x 120 x 180 mm

- Speed: up to 30 mm/h

- Layer Thickness: 35 µm

Anycubic Mega-S

The frame of the printer is made of aluminum. The platform heats up to 110 degrees Celsius. It has a color touch screen. When unpacking the device, you will need to connect the frame to the control unit. This is easily done using bolts and a few wires.

The package includes a cord for connecting a memory card and the card itself. Also, there's a one-kilogram spool of plastic, allowing beginners to experiment. The menu operates in multiple languages. A small detail with sides of 2 cm can be made in just half an hour.

Advantages:

- heated bed;

- color screen with convenient touch buttons;

- easy control and high printing accuracy;

- continues working even during power outages.

Disadvantages:

- sensitive to temperature fluctuations and drafts;

- no possibility to adjust the cooling.

- Number of Extruders: 1

- Maximum Extruder Temperature: 260°C

- Printing: FDM

- Printing Resolution: 2560*1440

- Travel Speed: 100 mm/s

- Print Bed Temperature: 110°C

- Printing Precision: XY: 12.5 µm, Z: 0.2 µm

- Build Volume: 210x210x205 mm

- Speed: 20-100 mm/s

- Supported Materials: PLA, ABS, TPU, HIPS, Wood

- Layer Thickness: 50 µm

- Filament Diameter: 1.75

- Nozzle Diameter, mm: 0.4

Before purchasing a 3D printer, you need to determine its intended use. Beginners do not need to buy expensive models for home use, as they are more suitable for professional use and creating high-precision models.

The main drawbacks of modern devices are the relatively high price, not only for the equipment itself but also for consumables. Additionally, 3D printers emit a pungent smell of burning plastic during operation.

It is worth noting that when choosing a resin-based printer, this consumable can be reused. A 3D printer allows you to create the necessary parts at home. Even small children will find it interesting to work with such a device and develop their own parts.