Description of the "MakerBot Replicator Z18" 3D printer

MakerBot Replicator Z18 is a 3D printer of MakerBot for large format printing. The name speaks for itself. "Z18" means "18 inches in the vertical plane", which gives a good idea of the true dimensions of the new printer's working chamber. In the horizontal plane, the dimensions are slightly more modest, but still impressive: 12 inches in the X and Y axes. In metric equivalent, it turns out to be 305x305x457mm, which is an order of magnitude higher than 252x199x150mm for the flagship model.About the "MakerBot Replicator Z18" printer

One of the main criticisms of the MakerBot Replicator 3D printers has always been the relatively small build area. The company has always countered such attacks, pointing to the possibility of printing large parts in parts, with subsequent assembly. Nevertheless, such an approach is more pragmatic when printing with ABS plastic, which is easily fusible (in essence, melting) with acetone. The "Replicators", however, are traditionally designed to work with polylactide (PLA plastic). However, it turns out that creating a professional and even industrial-grade printer with a large work area has long been in the company's plans. And now, it has come to pass. The fifth generation of MakerBot Replicator printers includes three models: the basic, flagship Replicator, the compact and inexpensive Replicator Mini, and the professional printer for large format printing, named Replicator Z18.

Design

The Replicator Z18 became the first targeted 3D printer of the MakerBot company for large format printingThe case is made in the same style as the fifth-generation counterparts: a load-bearing structure of steel and ABS plastic, strict but stylish lines – everything befitting a high-tech gadget. It creates the impression that the company is trying to erase the last reminders of its humble beginnings among the RepRap enthusiasts.

As with the Mini, the openings in the Z18 case are covered with transparent panels. Generally, this is not the best option for printers printing with PLA plastic, as polylactide takes a long time to cool. As a rule, in such cases, open cases are used, allowing to speed up the cooling process. So far, the MakerBot team has adhered to this unwritten rule, and the flagship has an open case. The developers explained the closed case of the Replicator Mini by the need to increase user safety, since this printer is intended for use in domestic and educational institutions, and curious children can easily get burned on the hot extruder. However, the choice of a closed case for the professional Z18 is not entirely understandable. All we can do is hope that the problem of ventilation and cooling was properly resolved by the designers – judging by the quality of the demonstrated models, it seems to be true.

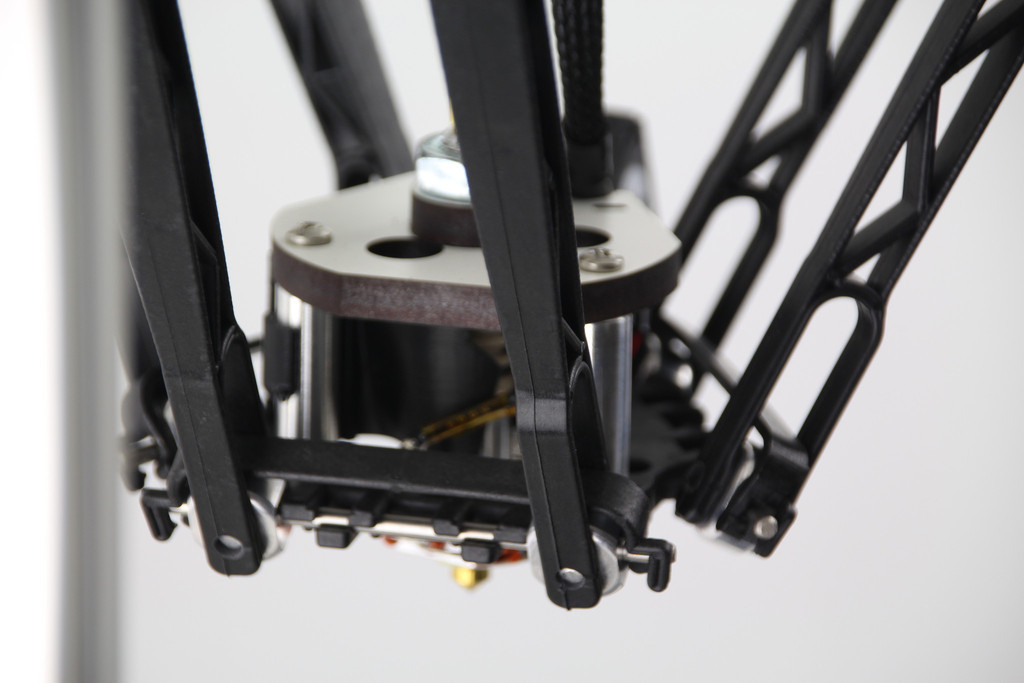

New extruder for MakerBot's fifth generation printersLike other counterparts, the Z18 is equipped with a new "smart" extruder. This print head is equipped with a special sensor that allows notifying the user when the consumable material is running out. The print automatically pauses waiting for a cartridge replacement. The importance of this feature cannot be overstated, especially considering the size of the parts being made with the Z18 – it would be a shame to lose a model just because the plastic ran out in the middle of the printing process, and neither the printer nor the user noticed the imminent trouble. In addition, the extruder is equipped with Hall sensors that allow for precise platform calibration.

However, there is also a fly in the ointment. The extruder used is universal and is used both on the Z18 and on the Mini and flagship. While there are no reports of the reliability of large and small "replicator" versions yet (preliminary orders are just being finalized at the moment), the flagship has already been tested with less than comforting results. Some users complain of a weak extruder feed mechanism and clogging. This problem can be exacerbated when using third-party consumables, the quality of which often does not meet the high standards of MakerBot materials. Oval filament cross-section or dust can easily incapacitate the extruder, and repairing it at home will be a difficult task. There is, however, an unusual advantage: the extruder is mounted only on strong magnets. If desired, the entire assembly can be "peeled off" and a new one can be inserted in its place, while the one that has failed can be sent to the service center.

The Replicator Z18 is equipped with a built-in camera for monitoring the printing processThere is also a built-in camera that allows remote monitoring of the printing process. Moreover, MakerBot is actively developing cloud support – as the company's CEO, Bre Pettis, says, now you can start printing and go to a cafe for a cup of tea, but at the same time watch the process with the help of a smartphone.

The workbench of the Z18 is made of a mixture of polycarbonate and ABS plastic. For better adhesion of the first layer, it is recommended to use regular masking tape with a wax impregnation. This method is well known and popular among DIY enthusiasts. You can either buy the tape yourself or purchase ready-made "size-to-size" coatings from MakerBot. Naturally, using a plastic workbench means the absence of platform heating. In principle, it is not needed, since PLA plastic has a very low degree of shrinkage, and the likelihood of the first layers twisting is minimal. In addition, the same closed case may contribute to uniform cooling and prevention of deformations.

Movable stand for Replicator Z18The size (493x565x854mm) and weight (41kg) of the printer pushed the developers to create a special stand on casters. Whether this stand is worth the promised $1,250 is a big question. Perhaps it would be simpler to find a permanent place for installation.

Printing

"Replicators" have always been praised for their good resolution and print accuracy. The designers of this company never promise anything fantastic, but they keep their word. The Z18 is designed for printing with a minimum layer thickness of 100 microns – an excellent indicator, and often even excessive. The positioning accuracy of the print head is also at a high level, reaching 11 microns in the X and Y axes, and 2.5 microns in the Z axis. And let's not forget about the work area volume, which allows for creating such masterpieces in full:

MakerBot CEO Bre Pettis before and after "plastic surgery"A special feature is the special spools of consumable material. If standard coils reach 1kg in weight, then special spools for the Z18 weigh a full 4.5kg. It is clear – large models require a large consumption of materials. In addition, it is possible to use smaller proprietary coils. The latter are loaded into the pull-out compartment built into the lower part of the device. Giant 4.5kg coils are supplied in their own case for external installation.

Special 4.5kg spools of consumable materialFortunately, the creators have left the possibility of using third-party consumables. There are no tricks to prevent the use of third-party consumables, unlike the printers of the competing 3D Systems company. The only obstacle is the non-standard size of the proprietary coils for the fifth generation, for which the internal compartments of the printers are designed. Nevertheless, non-proprietary coils can be installed on the outside.

Software

Like the other fifth generation "replicators", Z18 uses the MakerBot Desktop software package, which includes MakerWare for processing and slicing digital models, plus integration with the proprietary Thingiverse website and cloud support.

The MakerBot Desktop software package combines editor, slicer, and browser featuresCreating your own models is possible using standard CAD programs. Those who wish can use the proprietary MakerBot Digitizer 3D scanner for cloning existing physical models.

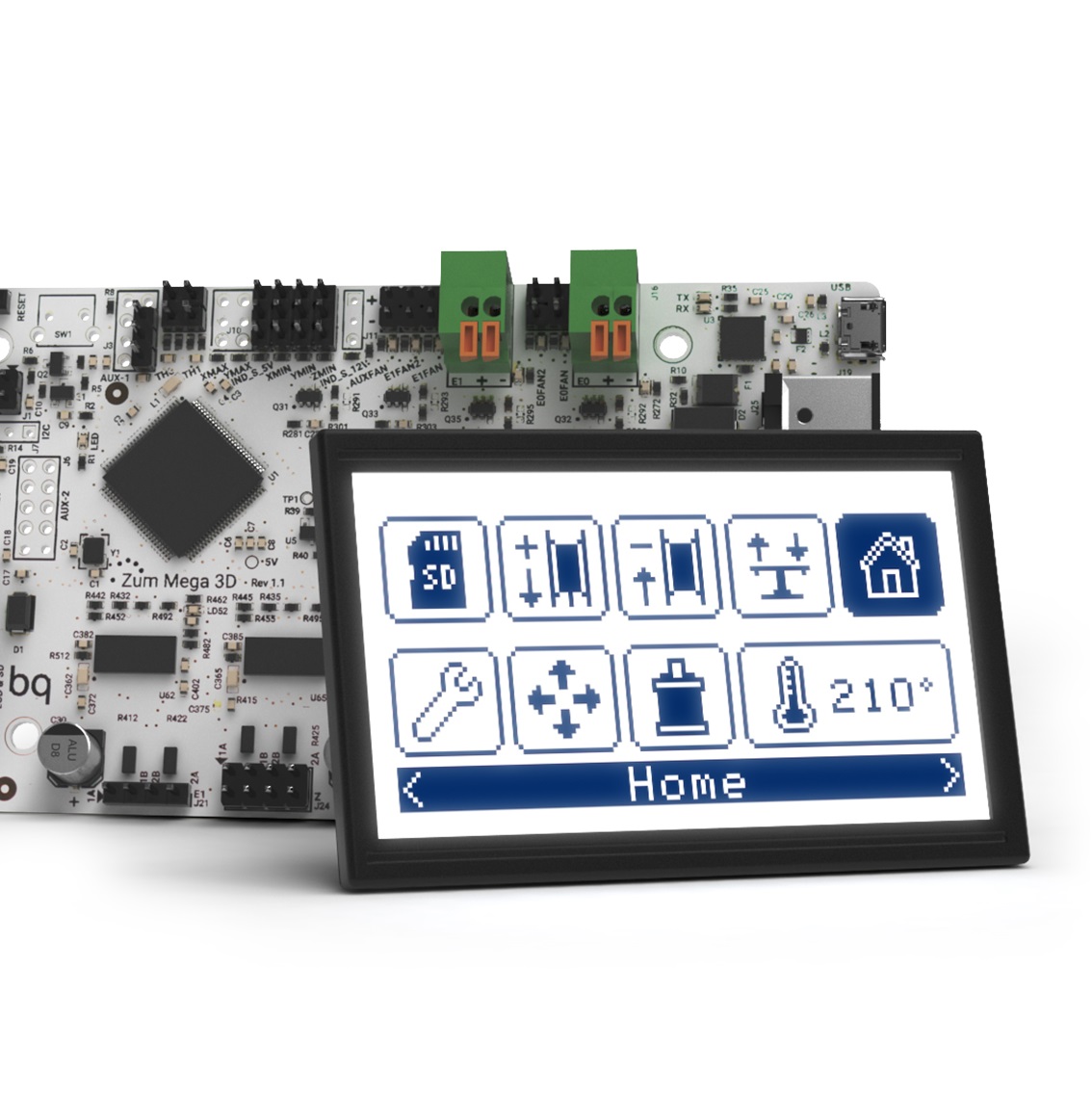

For data exchange, the Z18 is equipped with Ethernet interface and USB connection. The developers have abandoned SD cards in favor of USB drive support – autonomous printing is still possible. The Z18 is equipped with a control module similar to the module of the flagship. This includes a large LCD screen and a convenient rotating handle, "like expensive stereo systems". The designers did not want to deal with touch screens for now.

Summary

Replicator Z18 is a long-standing dream of the company's founder, Bre Pettis. Bre does not hide the fact that this device is intended not just for professional, but for industrial use. According to him, the Z18 will be actively used for prototyping and small-scale production by MakerBot itself. Nevertheless, the Z18 is no more difficult to use than the flagship Replicator, being perfectly manageable by the average user – an optimized design and software guarantee this.

Certain rawness of the new extruder and minor issues with the printer's firmware will undoubtedly be resolved over time. MakerBot has always taken its devices' quality and user tech support seriously. However, there is one serious drawback – the high cost. At the stated retail price of $6,499, this impressive 3D printer will only be affordable to well-off professionals.

Advantages

- Large build area

- High printing quality

- Convenience in use

Disadvantages

- Weaknesses in the extruder design and firmware

- High price

| Purpose | Personal |

| Country | USA |

| Manufacturer | MakerBot Industries, LLC |

| Technical Specifications | |

| Printing Technology | FDM/FFF |

| Number of print heads | 1 |

| Build area, mm | 305x305x457 |

| Interfaces | wi-fi, usb, ethernet |

| Display | Yes |

| Consumables | |

| Material Types | Plastic |

| Materials | PLA plastic |

| Filament diameter, mm | 1.75 |

| Software | |

| Software | MakerBot Desktop

File types: STL, OBJ, Thing, MakerBot |

| Dimensions | |

| Dimensions, mm | 493x565x854 |

| Weight, kg | 41 |

Printer Pricing

"MakerBot Replicator Z18" price listing

-

Amazon 10% Off

Buy "MakerBot Replicator Z18" printer on Amazone

$320 -

eBay used brand new

Buy "MakerBot Replicator Z18" printer on eBay

$???

There can be your clear opinion about MakerBot Replicator Z18