Description of the 3D printer "MakerBot Replicator Mini"

The MakerBot Replicator Mini is a compact version of the MakerBot Replicator desktop 3D printer, optimized for maximum convenience during operation. The dimensions of the device are 295x310x381mm with a maximum print size of 100x100x125mm. Printing is done with a single extruder using polylactide (PLA) as the consumable material. The minimum layer thickness is 200 microns. The device is equipped with a USB port and a wireless interface (Wi-Fi).

About the "MakerBot Replicator Mini" printer

The year 2014 was significant in MakerBot's history. For the first time, the developers released not just a new model of their famous Replicator 3D printer, but immediately three versions. The first one is the same flagship design, perfected and polished. But alongside the standard "Replicator," the company introduced the Replicator Z18 and the Replicator Mini. In this lineup, the standard Replicator serves as the golden mean, while the Z18 provides increased production capabilities due to the enlarged workspace, and the Mini goes in the opposite direction – it's a compact, user-friendly device at a very affordable price. If the flagship is intended for enthusiasts and the Z18 for professionals, then the Mini is meant to occupy its own niche called household 3D printing.

Design

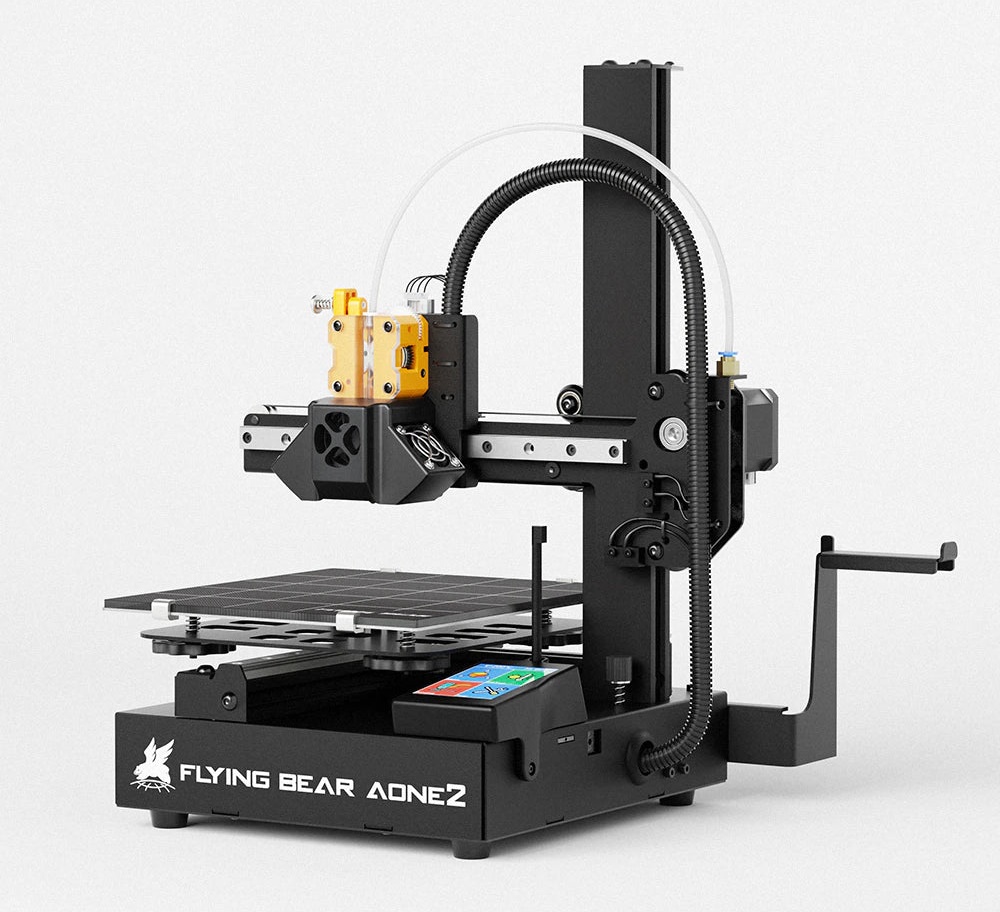

The MakerBot Replicator Mini is a compact version of the famous "replicator"The Replicator Mini is a compact version of the Replicator printer. This could be enough to stop at, as the entire MakerBot fifth-generation printer line has many common features. Nevertheless, there are differences, and they are quite targeted.

The external resemblance is undeniable. The same strict, but attractive design, almost without a hint of the roots of MakerBot printers in the RepRap project. Load-bearing design made of steel and ABS plastic. The absence of a control module is immediately noticeable – the front panel has only one button to start printing.

All preparatory functions are carried out exclusively with the help of a computer, or by the printer itself, but automatically. So, MakerBot developers first automated the process of calibrating the work platform. We remind you that on other fifth-generation printers, as well as the parallel fourth generation, calibration is performed in semi-automatic mode. The new flagship even comes equipped with Hall sensors, accurately measuring the distance between the nozzle and the worktable, but the tilt of the platform still needs to be adjusted manually. On the Mini, this process was completely automated for the sake of ease of use.

The printer’s housing with characteristic side and front openings is closed with transparent panels. This is a somewhat controversial decision because the Mini is exclusively intended for printing polylactide (PLA plastic), and this material tends to cool down quite slowly. A closed housing helps maintain an elevated temperature in the workspace, which is extremely useful when printing materials such as ABS, nylon, or polycarbonates, but has the opposite effect when printing PLA. If the fresh layers don't have enough time to cool, their "flowing" is possible, which is the deformation of the model. However, the developers have a weighty argument for this solution: the Mini is designed for household and school use, and the closed housing allows you to protect small curious hands from burns.

Built-in camera for remote control of the printing processOne interesting feature is the installation of a camera that displays the process status in real time. The user gets the opportunity to visually control the printing progress, including through mobile devices.

Printing

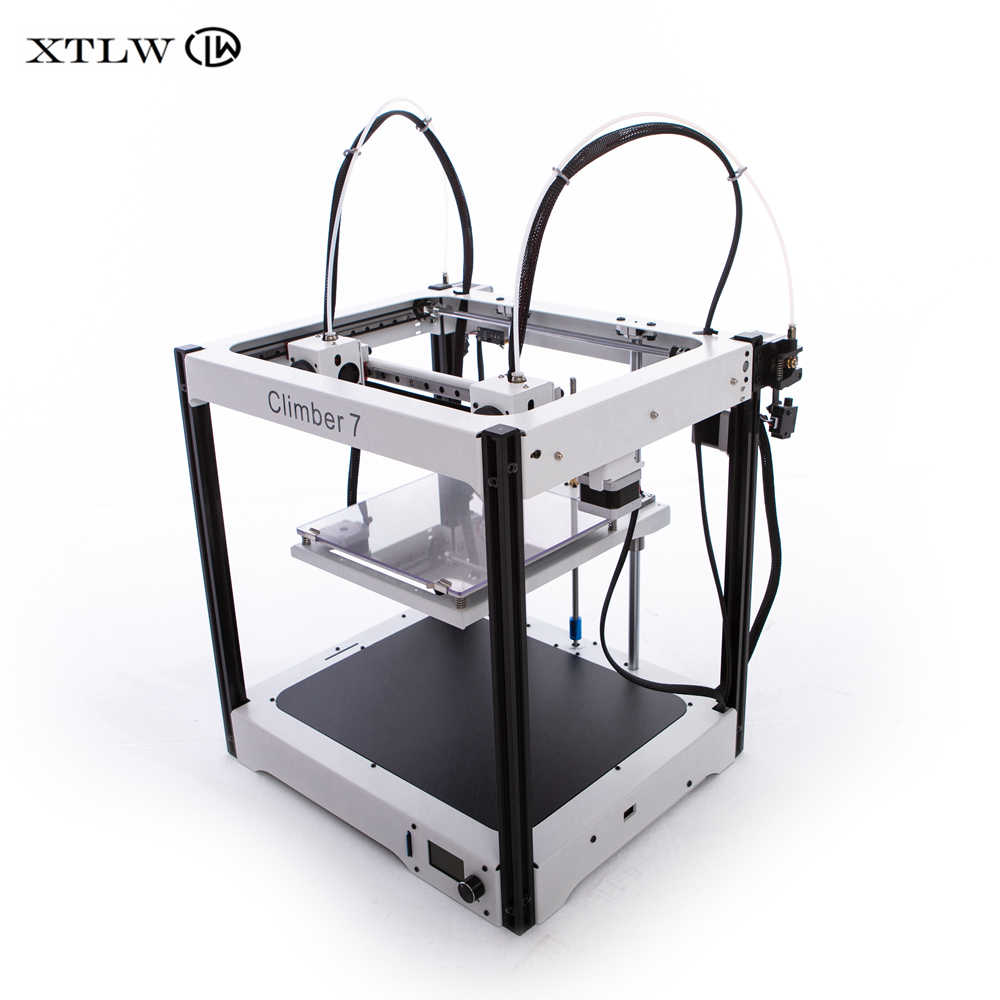

Like the flagship, the Mini is equipped with a new "smart" extruder, equipped with Hall sensors for calibration and a special sensor that warns of the end of the feed of consumable material. This eliminates the possibility of printing "in the air" with the inevitable writing off of a semi-finished model. All the user needs to do is replace the spool with the thread and give the command to continue printing.

New extruder for MakerBot fifth-generation printersThe area of the Replicator Mini building is quite modest, reaching 100x100x125mm, but this is the inevitable price for the compact dimensions of the printer itself – only 295x310x381mm.

The minimum thickness of the applied layer has been increased to 200 microns. In principle, this is not a technical limitation of the printer itself, but a recommended setting by designers. According to Bre Pettis, CEO of MakerBot, the team mainly prints with a resolution of 200 microns, achieving acceptable results in most cases. Plus, this results in faster printing.

The acrylic worktable is covered with painter's tape before printingSince the Mini is intended for printing only with PLA plastic, the work platform is not equipped with a heater. The tabletop is made of acrylic, unlike the glass used in the flagship. In principle, both materials are well suited for the intended purpose, especially since MakerBot recommends covering the table with painter's tape – a proven solution for PLA printing, popular among RepRap enthusiasts. The wax coating of the tape adheres well to the lower layer of the model, holding it in place. PLA plastic is valued for its unpretentiousness, being practically immune to deformation (especially when printing small models, as in the case of the Replicator Mini), and does not emit toxic fumes or unpleasant odors.

Overall, there should be no problems with printing. At least, not problems related to the use of PLA. Unfortunately, the new extruders have received a lot of complaints. The more complex the device, the higher the chances of breakage – the extruders of the fifth-generation "replicators" confirm the validity of this axiom. Mostly, the problems boil down to a fairly weak feeding mechanism. As for the repair or cleaning of the extruder by the owner, such an undertaking may not be possible for everyone. However, the new extruders are easy to remove and replace, as they are attached only by magnets. But what then? The company offers technical support, but their network of service centers and stores has not yet been developed in Russia. You can only hope for local, non-proprietary service centers, or send the part back and wait for a replacement, which takes quite a long time.

Software

It should be noted that, unlike the flagship and the Z18, the Mini is not equipped with an Ethernet interface. Designers considered connecting to a local network unnecessary for a printer primarily intended for household use. On the other hand, the Mini is equipped with Wi-Fi connection and a standard USB port. The latter allows you to connect directly to a computer or use USB drives.

MakerBot Desktop's proprietary softwareThe main software used is MakerBot Desktop – a software package that includes editor, slicer, and browser functions. Thanks to the development of the company's Thingiverse website into the cloud network, the user gets the opportunity to store their models on remote servers and print ready-made digital models posted on the site – most of which are provided for free. Of course, those willing can share their creations with other site users by posting the relevant files for public access – quid pro quo.

The simplest way of the printing process involves connecting the printer to a computer, finding a suitable model on the Thingiverse site using MakerBot Desktop, and giving the command to print. It couldn't be easier.

Conclusion

Replicator Mini is a great choice for household and educational 3D printingUniversal technology inevitably finds various applications. Having made a name for itself on successful semi-professional level 3D printers, MakerBot decided to cover a wide segment of the market with a whole range of 3D printers based on a single unified platform. The MakerBot Mini was created with the following requirements in mind: inexpensive, simple, fast, convenient, and safe. It can be said that all the set goals were achieved with the attainment of a good balance of often opposite qualities. We won't attribute the small build area of the Mini as a disadvantage, as the designers intentionally designed it as a compact device. Those wishing to print larger models can use the end of the spectrum – a professional MakerBot Z18. Perhaps, the only obvious shortcomings are the relative rawness of the printers, especially the new "smart" extruders, and the relatively high price of the brand as a whole. The latter is not a serious offense, because MakerBot offers additional features and print quality that are absent in most budget models.

Advantages

- Maximum simplicity and ease of use

- Good print quality

- Compact dimensions

- Safety

Shortcomings

- Initial batches showed some "rawness" of certain novelties

- Relatively high price

| Purpose | Personal |

| Country | USA |

| Manufacturer | MakerBot Industries, LLC |

| Technical Characteristics | |

| Printing Technology | Fused Deposition Modeling (FDM/FFF) |

| Number of Print Heads | 1 |

| Build Area, mm | 100x100x125 |

| Interfaces | Wi-Fi, USB |

| Consumables | |

| Material Types | Plastic |

| Materials | PLA plastic |

| Filament Diameter, mm | 1.75 |

| Software | |

| Software | Software: MakerBot Desktop

File Types: STL, OBJ, Thing, MakerBot |

| Dimensions | |

| Dimensions, mm | 295x310x381 |

| Weight, kg | 8 |

Printer Pricing

"MakerBot Replicator Mini" price listing

-

Amazon 10% Off

Buy "MakerBot Replicator Mini" printer on Amazone

$320 -

eBay used brand new

Buy "MakerBot Replicator Mini" printer on eBay

$???

There can be your clear opinion about MakerBot Replicator Mini