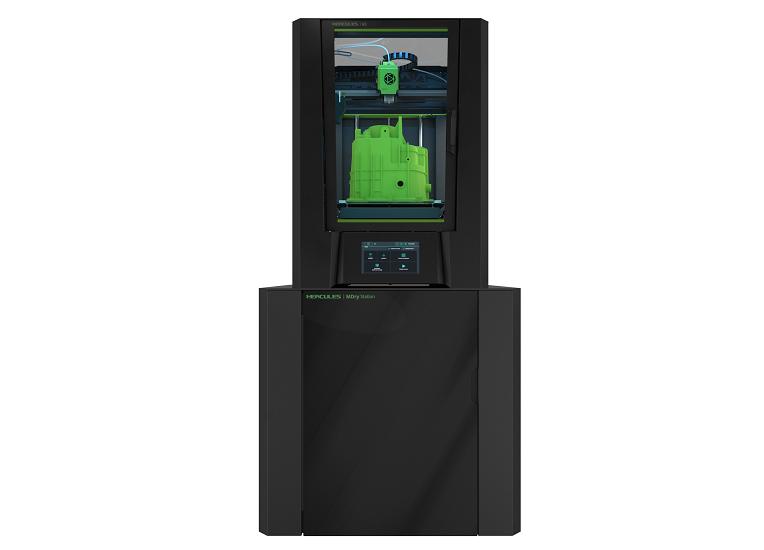

Description of the 3D printer "Cube 2"

Prague: The printer Cube is one of the leaders in the market of home 3D devices. Small dimensions of 26x26x34 cm and a weight of 9.5 kg with a cartridge make it sufficiently mobile. The device is equipped with a Wi-Fi module for wireless communication with a computer, and the print area is 14x14x14 cm. Even a child can handle the management of this printer thanks to the simplicity of the setup and intuitive control.About the "Cube 2" printer

Overview of the 3D printer Cube 3D

Printer Cube 3D - with nothing extra. As we have already mentioned, the 3D printer Cube from the American manufacturer 3D Systems became the first device of its kind to go on retail sale in Russia. It's time to take a closer look at the popular design and understand the pros and cons. The main thing to remember for the buyer is that Cube 3D is designed for amateur household printing. Do not expect super high quality models or unlimited modification options. This device is quite limited in its capabilities, but what it can do, it does well, without requiring any serious efforts from the user. The fundamental principle of the design can be described in two words: ease of use. Complete set of Cube 3D The first thing that catches the eye is the cleanliness and neatness of the design. Wiring, motors, and other moving and potentially dangerous mechanisms are tucked away in the housing. No wonder this device became one of the first 3D printers certified for "child use." The front panel of the printer is adorned with a touch screen, a metal platform rests in the working area, a USB port is visible on the right side, and a niche for inserting a cartridge with consumable plastic is located on the left side. And let's start from plastic. Cube 3D is hard to call cheap even at the manufacturer's retail price of about $1,300, and even more so at the Russian retail price of about 95 thousand rubles. Too much, although it is not the limit for desktop devices. And another thing is disturbing: most printers of this class allow the use of materials from different independent manufacturers - at your own risk, of course. Cube 3D users do not have this option. Printing is possible only with branded cartridges, and the tricky touch system does not allow cheating: if you insert a branded cartridge and try to lead the plastic filament to the print head from a "non-branded" coil, Cube refuses to obey. The question is, how much material is supplied in one branded cartridge? The manufacturing company, as well as retail sellers, modestly keep silent, although the task is solved by elementary weighing of an empty and full cartridge: the weight difference is only 320g. In total: 1.5 rub. per gram of cheap Chinese plastic or 8.5 rub. per gram of branded. Let's leave the costs on the conscience of 3D Systems and retail networks. Cube 3D uses only branded cartridges of 16 colors Cube 3D is equipped with one extruder, which means printing with one material and one color. There is nothing unusual in this. Many of the desktop printers are equipped with one extruder, but some of them can be modernized by installing a double or even triple head. In the case of Cube, the possibility of such modification by makeshift methods is unlikely, and not worthwhile. The range of colors includes sixteen shades. Another interesting point is that as consumables, polylactide (environmentally friendly, biodegradable, but quite short-lived) and ABS plastic (the same qualities as polylactide, but the other way around) are offered. Despite the popularity of the latter, printing with ABS plastic is fraught with certain difficulties, as it tends to deform when cooling unevenly and does not adhere well to the working surface. Practically all manufacturers of 3D printers use the same means to combat these unpleasant phenomena, namely - heating the working platform. Cube 3D was no exception (be careful, don't burn yourself!), but the results are somewhat ambiguous: despite heating, large area models are still prone to deformation. The cause is most likely the uneven heating of the platform. Although with a small print, the likelihood of success increases, do not be surprised if you get the so-called "angel's hair" - when the edge of the model deforms upwards, after which the moving nozzle hits the printed layers and removes the model from its place. Meanwhile, the head continues its ingenious dance, spilling plastic and the money invested in it. Nothing dangerous for the printer in this, the plastic hardens quickly and does not damage the device, but if you do not stop the printing in time, then the expensive material will be wasted in vain on the production of plastic vermicelli. It should be noted that problems with ABS plastic are not unique to Cube 3D. Model deformation and possible consequences, including the notorious "vermicelli" With polylactide, things are much better. It is worth keeping in mind that the thickness of the applied layer is 200μm and cannot be adjusted. On the one hand, this is not the highest indicator - 100μm is considered an unofficial standard, but it is far from the lowest. In general, the resolution is high enough for the production of quite attractive models, but with a very close examination, the layered structure will be noticeable. On the other hand, the smaller the layer thickness, the longer the printing time. For a purely amateur device, 200μm can be considered a reasonable "golden mean." It should also be noted that, alongside the plastic, the user will need to buy a special glue, which is applied to the work platform immediately before printing. As you have already guessed, the glue is intended to hold the bottom layer of the model in place and prevent the aforementioned "vermicelli." The glue dissolves in water, which allows the ready-made model to be easily separated from the platform - a couple of minutes in the bath will be enough. However, the branded glue is not cheap. Experienced enthusiasts prefer to use inexpensive double-sided adhesive tape. The platform easily detaches and reattaches without any difficulty. This is a definite plus. It's easy to remove the platform The process of loading the material is extremely simple: you install the cartridge in the niche, push the plastic filament into the guide tube, and insert it into the extruder. A couple of touches of the touch screen, and the capture takes place. The calibration of the platform is somewhat more complicated. Automatic calibration is not provided, and the inclination must be adjusted manually. However, the convenient interface of the printer makes the task as easy as possible. The interface will help with calibration, but you have to adjust the position of the platform manually, tweaking the screws All that remains to be done is to select the required file for printing in the menu and wait for the printer to conjure up the finished model. And here, one strange feature of Cube 3D emerges: it turns out that data transfer for printing via the USB port is possible only through the included "flash drive." Direct transfer from the computer is not possible - the connection is used only for firmware updates. At the same time, the printer is equipped with a Wi-Fi interface - which is the main wireless method of transfer. Here's what the Cube 3D editor looks like Cube 3D does not come with graphic editors as such. It only includes a program for importing and processing finished models, which can be created using third-party programs or purchased ready-made - 3D Systems has launched the Cubify website, where there is a rich assortment of ready designs. But bear in mind that not all models on the site are suitable for printing with the Cube 3D printer. Some of them are manufactured to order using professional equipment and supplied ready-made. In general, any model in the standard STL format can be used - even from the popular Thingiverse website. However, here it is worth considering another point: many of the models presented on "foreign" sites may require fine-tuning the printer, and in the case of Cube, this is simply impossible. The same Thingiverse was created with the more versatile MakerBot Replicator in mind. Accordingly, there are no guarantees that models from external sites will be printed as intended by the designers. If desired, on the Cubify website, you can purchase branded professional 3D design programs at a price ranging from $80 to $800, although this is not a mandatory requirement. But you will have to register your printer - in return, the user receives a four-digit code that needs to be entered into the device for its activation. The printer's software itself is very convenient and has several interesting features. One of them, the "treatment" function, automatically corrects imported designs, eliminating obvious defects like missed support and, in general, fitting the digital model for printing on Cube 3D - a good function for "non-native" designs. There is also a wonderful range of model structures to choose from: "hollow", "solid", or "strong". The first two names speak for themselves - a banal cube can be made hollow inside, but quite fragile, or solid and strong, but with a high material cost. The third option allows you to create seemingly solid models, filled with internal struts - it turns out to be a lightweight and strong product, with material savings. Moreover, after starting the print, the printer informs the user of the approximate duration of the cycle, with enviable accuracy.Summing up:

Advantages:

- Light, compact, pleasant design

- Convenient, intuitive interface

- Quite high print quality

Disadvantages:

- High cost of exclusive consumables

- Limited setup options

- A fairly high probability of failures when printing with ABS plastic

On the whole, Cube is perfect for those who do not want to delve into all the subtleties of the 3D printing process. The printer requires only minimal maintenance and setup, is practically ready to print "right out of the box" and boasts quite good quality of manufactured models. True enthusiasts may be disappointed with the rather limited capabilities of Cube and the actual lack of the possibility of modification or fine tuning. If you can afford the quite expensive branded cartridges, Cube will be an excellent tool for producing all sorts of useful trinkets for the home, toys for children, and souvenirs for friends.

| Purpose | Personal |

| Country | USA |

| Manufacturer | 3D Systems |

| Technical Specifications | |

| Printing Technology | Plastic Jet Printing (PJP) |

| Number of print heads | 1 |

| Build area, mm | 140x140x140 |

| Print speed | 15 mm3/sec |

| Platform | No heating |

| Interfaces | wi-fi, usb |

| Display | Yes |

| Consumables | |

| Types of materials | Plastic |

| Materials | ABS plastic, PLA plastic |

| Software | |

| Software | Cube Software for Windows and MAC |

| Dimensions | |

| Dimensions, mm | 260x260x340 |

| Weight, kg | 4.3 |

Printer Pricing

"Cube 2" price listing

-

Amazon 10% Off

Buy "Cube 2" printer on Amazone

$320 -

eBay used brand new

Buy "Cube 2" printer on eBay

$???

There can be your clear opinion about Cube 2